A China é rica em recursos minerais de quartzo, amplamente classificados em três categorias: quartzo, tridimita e cristobalita. Em aplicações industriais, diversos processos de beneficiamento do minério de quartzo, incluindo a moagem intensiva, são utilizados para purificação e processamento, resultando em produtos como pedra de quartzo e areia de quartzo. A pedra de quartzo e a areia de quartzo processadas apresentam aparência poliédrica ou esférica, possuem alta resistência mecânica, excelente capacidade de retenção de impurezas e superior resistência a ácidos. Essas características as tornam amplamente utilizadas em diversos setores industriais.

Os processos de beneficiamento de areia de quartzo comumente usados na produção incluem: lavagem e deslamagem, separação magnética, flotação e lixiviação ácidaEsses métodos oferecem vantagens como produção em larga escala, altos graus de purificação e alta eficiência. A seguir, detalhamos os processos específicos de beneficiamento do minério de quartzo, os tipos de equipamentos necessários e como eles são logicamente integrados em uma linha de produção completa de beneficiamento de minério de quartzo.

As etapas essenciais no beneficiamento do quartzo determinam a seleção dos equipamentos de processamento, que são então integrados em uma linha de produção. Geralmente, todos os processos de beneficiamento seguem uma sequência: britagem-moagem/trituração-separação/purificação (utilizando equipamentos como separadores magnéticos e máquinas de flotação) –secagem por concentração.

Embora o fluxo específico possa variar de acordo com as características minerais reais, os estágios principais são sempre Trituração, moagem, separação (purificação) e concentração.O beneficiamento do minério de quartzo gira em torno destas etapas para separar e purificar o minério de quartzo.

Processo de britagem (classificação por tamanho)

A etapa de britagem utiliza equipamentos como britadores de mandíbula e britadores de cone para reduzir o minério de quartzo a um tamanho de partícula específico. O material é normalmente britado até um tamanho adequado para a próxima etapa, geralmente 25 mm ou menores. Obter um tamanho mais fino nesta fase é sempre benéfico para a operação de moagem subsequente.

Processo de moagem/trituração (redução de partículas)

A etapa de moagem utiliza moinhos de bolas especializados para moagem de minério de quartzo, a fim de processar o material triturado. A moagem reduz o tamanho das partículas do minério de quartzo, frequentemente para uma faixa de 0,074 mm a 0,89 mm ou até mesmo mais fina para aplicações de alta pureza, o que é essencial para a classificação e purificação subsequentes e eficazes. Para atingir a finura desejada de forma eficiente, os operadores devem seguir rigorosamente os requisitos de tamanho da alimentação.

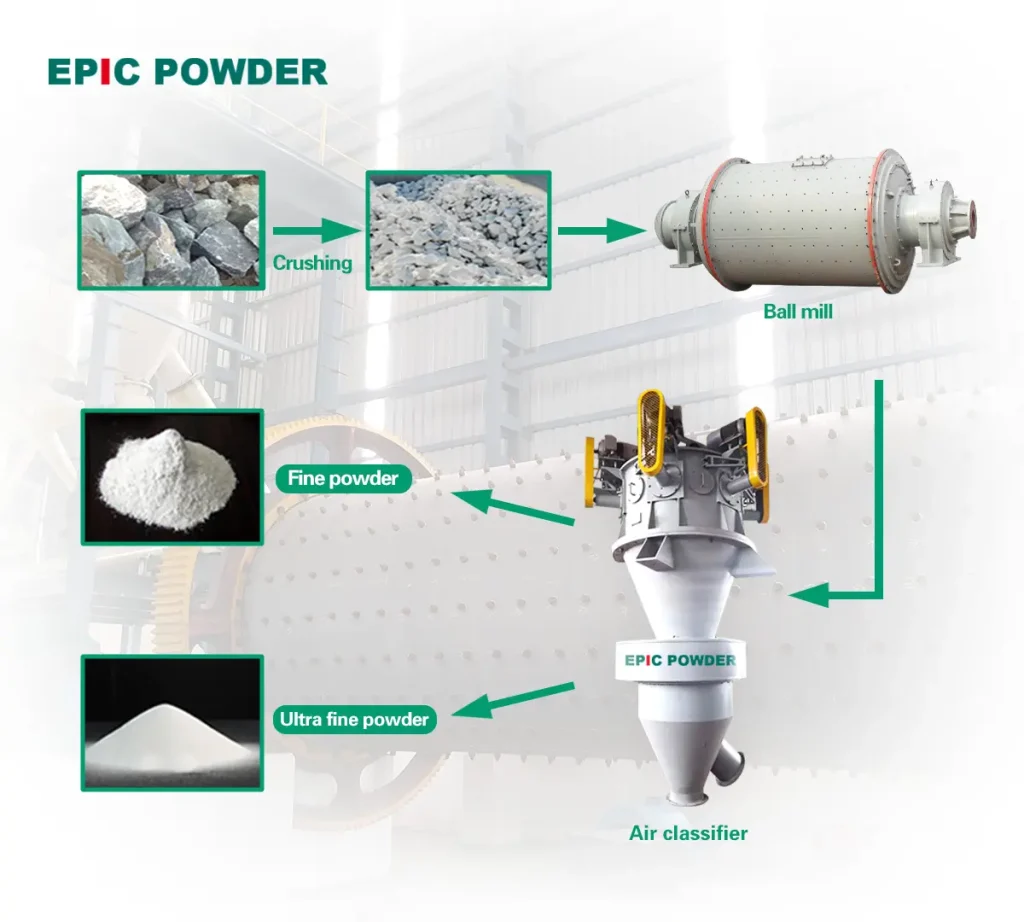

Soluções de moagem e classificação da Epic Powder Machinery

Como especialistas em processamento de pó, Maquinaria Epic Powder Oferece soluções avançadas cruciais para as etapas de moagem e classificação no processamento de quartzo de alta pureza.

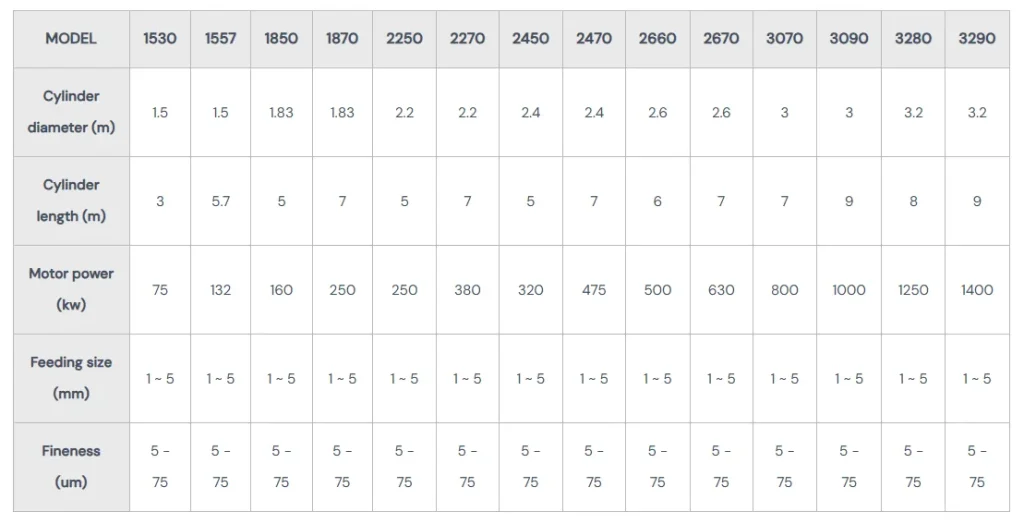

Moinhos de bolas:

Utilizados para a moagem a úmido ou a seco de materiais. No processamento de quartzo, os moinhos de bolas são essenciais para reduzir o minério de quartzo à finura precisa necessária para uma purificação eficaz. Eles operam girando um cilindro preenchido com esferas de moagem, que impactam e abrasam o material. Nossos moinhos de bolas são projetados para alta produtividade e podem ser personalizados com revestimentos e esferas especiais para minimizar a contaminação por ferro, um fator crítico na produção de quartzo de alta pureza.

Classificadores de ar:

Utilizados no processamento a seco para separar partículas de pó com base em seu tamanho e densidade. Na produção de pós de quartzo ultrafinos para materiais avançados, os classificadores de ar são frequentemente combinados com moinhos de jato ou moinhos de bolas para controlar com precisão o limite superior do tamanho das partículas do produto final, garantindo uma distribuição granulométrica estreita para aplicações específicas de alta tecnologia.

Moinhos a jato:

Utilizados para moagem ultrafina de materiais em partículas com tamanho submicrométrico ou micrométrico. Para produtos de quartzo de altíssima pureza (por exemplo, para eletrônica e óptica), os moinhos de jato podem atingir a extrema finura necessária utilizando gás em alta velocidade para provocar a colisão das partículas, minimizando o desgaste e a contaminação.

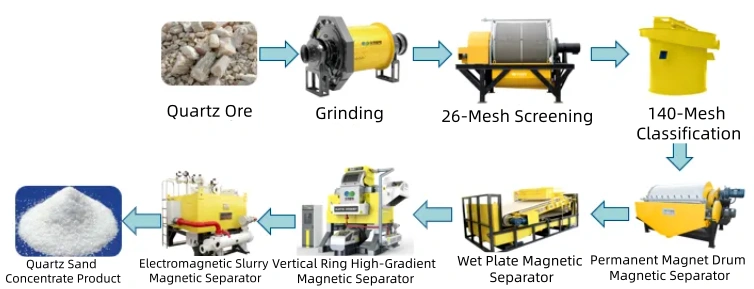

Processo de Separação (Purificação)

A linha de purificação normalmente consiste em classificadores, separadores magnéticos, e máquinas de flutuaçãoO princípio é proceder da seleção inicial à seleção final.

Primeiro, classificadores ou classificadores espirais Lave e separe o pó de quartzo moído. Em seguida, separadores magnéticos Realizar uma separação preliminar para remover impurezas magnéticas, como minerais que contêm ferro. Finalmente, máquinas de flutuação pode ainda separar a substância de quartzo desejada dos complexos minerais associados.

Processo de concentração (desidratação e secagem)

O espessantes e equipamentos de secagem É possível desidratar e secar a substância de quartzo separada. Isso resulta em um produto final de quartzo seco e de alta pureza, pronto para aplicação direta em setores industriais.

Em resumo, o processo de beneficiamento do quartzo envolve:

- Esmagamento o minério de quartzo bruto.

- Moagem o material usando um moinho de bolas.

- Lavagem e dimensionamento usando um classificador.

- Separando impurezas com um separador magnético e uma máquina de flotação.

- Drenagem com um espessante e Secagem com equipamento de secagem para obter a matéria-prima de quartzo de alta pureza necessária.

Na prática do beneficiamento, os engenheiros devem determinar o processo ideal para a areia de quartzo, avaliando de forma abrangente as características do minério de quartzo, as condições da planta e o orçamento de investimento. Recomendamos fortemente a realização de testes de beneficiamento prévios, o que possibilita a seleção de um fluxo de processo único ou combinado que proporcione os melhores benefícios econômicos.

Pó épico

Pó épico A Epic possui mais de 20 anos de experiência na indústria de pós ultrafinos. Promovemos ativamente o desenvolvimento futuro em britagem, moagem, classificação e modificação. Um foco chave em P&D é a tecnologia de micropó de silício. Este material é crucial para a embalagem de chips semicondutores e para a preparação de laminados revestidos de cobre. Isso inclui moinhos de bolas, classificadores e moinhos de jato. Os equipamentos da Epic impulsionam a expansão e o progresso tecnológico do quartzo ultrafino, resultando na modernização industrial em áreas de produtos relacionados.

Obrigado pela leitura. Espero que meu artigo tenha ajudado. Deixe um comentário abaixo. Você também pode entrar em contato com o atendimento ao cliente da EPIC Powder online. Zelda Para quaisquer outras dúvidas, entre em contato com um representante.”

— Publicado por Emily Chen, Engenheiro