В современном промышленном производстве кварц обычно обрабатывается с помощью интегрированной системы измельчения и классификации, включающей струйную мельницу и воздушный классификатор. Давайте уточним роли этих двух ключевых элементов оборудования.

Разъяснение основных понятий: струйная мельница против классификационной мельницы.

Струйная мельница (воздушная струйная мельница): Основной принцип его работы заключается в уменьшении размера частиц или измельчении. Он использует сверхзвуковой сжатый воздух для ускорения частиц, заставляя их сталкиваться друг с другом и распадаться. Важно отметить, что автономная струйная мельница не включает в себя функцию точной классификации.

Классификатор воздуха: Основной принцип работы — разделение. Система разделяет уже измельченные материалы по размеру частиц, используя центробежную силу и поток воздуха. Система собирает мелкие частицы и отбрасывает крупные для дальнейшего измельчения.

Термин Воздух Классификационная мельница обычно относится к Механическая ударная мельница со встроенным классификационным колесом (например, вертикальная вальцовая мельница). Этот тип оборудования объединяет дробление и предварительную сортировку в одном устройстве.

Предпочтительный процесс обработки кварца: струйная мельница + система воздушной классификации.

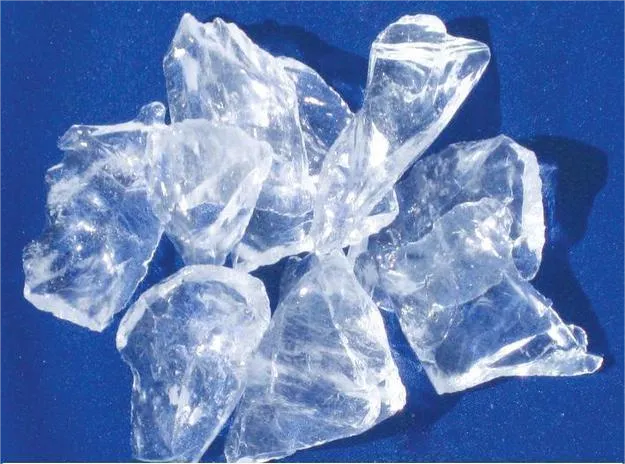

Для твердых материалов, таких как кварц (твердость по шкале Мооса 7), требующих строгой чистоты и плотного распределения частиц по размерам, система Jet Mill + High-Efficiency Dynamic Air Classifier представляет собой передовую и широко распространенную в отрасли конфигурацию.

Как работает интегрированная система:

- Предварительно измельченное кварцевое сырье подается в камеру измельчения струйной мельницы.

- Сверхзвуковые сопла ускоряют частицы и измельчают их, главным образом, за счет столкновений между частицами.

- Затем воздушный поток транспортирует измельченный материал в высокоэффективный динамический воздушный классификатор, который обычно устанавливается на мельнице или интегрируется с ней.

- Вращающееся на высокой скорости колесо классификатора действует как прецизионный «экран», пропуская через него только мелкие частицы, меньшие, чем заданная пороговая величина, в качестве конечного продукта.

- Классификационное колесо отбрасывает крупные частицы и автоматически возвращает их в камеру струйной мельницы для дальнейшего измельчения.

Почему эта система является высшим стандартом качества кварца?

Гарантированная высокая чистота: Струйное измельчение — это чисто физический процесс без движущихся шлифовальных частей. Это приводит к минимальному износу оборудования и предотвращает загрязнение металлическими частицами, что крайне важно для получения кварца высокой чистоты — огромное преимущество перед механическими мельницами.

Точный контроль размера частиц: Независимый высокоэффективный воздушный классификатор обеспечивает чрезвычайно точный контроль верхней границы фракции конечного продукта (D97). Он легко позволяет получать сверхтонкие порошки с узким и равномерным распределением частиц по размерам.

Низкий уровень загрязнения железом: Производители могут облицовывать все внутренние поверхности системы керамикой, полиуретаном или другими износостойкими материалами, что обеспечивает чрезвычайно низкое содержание железа в изделии.

Высокая эффективность: Система замкнутого цикла непрерывно перерабатывает крупногабаритный материал для повторного измельчения, что позволяет максимально повысить общую эффективность измельчения и предотвратить потери энергии на уже соответствующие техническим требованиям мелкие фракции.

Почему бы не использовать автономную пневматическую классификационную мельницу?

Хотя механические ударные мельницы со встроенными классификаторами имеют свое место (например, для более мягких минералов, таких как карбонат кальция, к чистоте которых предъявляются более низкие требования), они демонстрируют существенные недостатки при обработке кварца:

- Риск загрязнения: Вальцы, штифты и столы механической мельницы подвергаются сильному износу при обработке твердого кварца, что приводит к попаданию в него примесей железа и других металлов. Это делает их непригодными для высокотехнологичных применений, таких как солнечные фотоэлектрические системы или кварц полупроводникового качества.

- Ограничение по тонкости помола: Для очень мелких порошков (например, D97 < 20 мкм) энергия измельчения и точность классификации интегрированной классификационной мельницы часто уступают специализированной системе струйной мельницы-классификатора.

- Быстрый износ компонентов: Обработка кварца приводит к сильному износу расходных деталей мельницы, что влечет за собой увеличение затрат на техническое обслуживание и простои.

Краткое сравнение

| Особенность | Система струйной мельницы + воздушного классификатора | Механическая ударная мельница (классификаторная мельница) |

| Принцип работы | Столкновение частиц + Внешняя классификация точности | Ударное воздействие и сжатие + Внутренняя предварительная классификация |

| Чистота конечного продукта | Чрезвычайно высокийотсутствие металлических загрязнений | Снижен риск загрязнения из-за износа. |

| Тонкость конечного продукта | Способный сверхтонкое, узкое распределение порошки | Наиболее эффективен для порошков средней тонкости; менее эффективен для сверхтонких порошков. |

| Износ оборудования | Очень низкий | Значительный |

| Потребление энергии | Выше (относительно) | Ниже (относительно) |

| Идеально подходит для | Высококачественный кварц:Полупроводники, солнечные фотоэлектрические элементы, высококачественные наполнители | Стандартный кварцевый механизм: Конструкция, керамический корпус и т. д. |

Для производства высокочистого и ценного кварцевого порошка для таких применений, как полупроводники, фотовольтаика и современные покрытия, интегрированная система струйной мельницы и воздушного классификатора является безусловным выбором. Для стандартных применений, где чистота и точный размер частиц менее критичны, может использоваться экономичная механическая ударная мельница.

Эпический порошок

Являясь ведущим новатором в области технологий уменьшения размеров, Эпический порошок Компания Machinery специализируется на проектировании и производстве современных систем измельчения. Мы предлагаем индивидуальные решения, включая описанные выше струйные мельницы и системы воздушного классификатора, обеспечивающие высокую чистоту, точный контроль размера частиц и исключительную эффективность для таких сложных задач, как переработка кварца. Свяжитесь с нами по телефону: минерал@epic-powder.com.

Спасибо за прочтение. Надеюсь, моя статья вам поможет. Пожалуйста, оставьте комментарий ниже. Вы также можете связаться с онлайн-представителем EPIC Powder. Зельда для любых дальнейших запросов».

— Джейсон Ван, Старший инженер