Кварц Это один из самых распространённых и универсальных минералов на Земле, играющий важнейшую роль во многих отраслях промышленности, от строительства до высокотехнологичной электроники. Для процесса от переработки минерального сырья до тонко измельченного порошка требуется современное оборудование, такое как кварцевый мельница для помола Становится необходимым. Понимание свойств кварца и особенностей его обработки — ключ к раскрытию его полного потенциала.

1. Минералогические характеристики и основные свойства

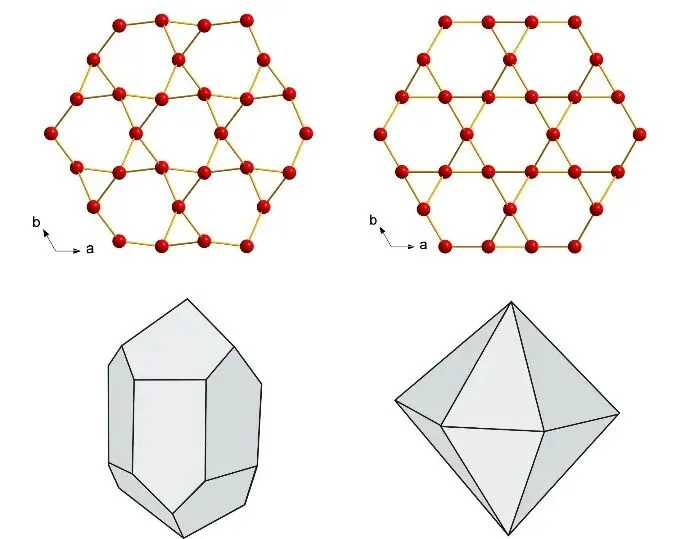

Кварц (SiO₂) — оксид кремния с каркасной структурой. Обычно его называют α-кварцем (низкотемпературным кварцем, тригональной сингонии) и β-кварцем (высокотемпературным кварцем, гексагональной сингонии) с температурой фазового перехода 573 °C. Под неуточнённым кварцем обычно подразумевается α-кварц.

В минералогической классификации кварц относится к классу оксидов и группе кварца. Иногда, благодаря своему положению в конце ряда силикатов, его также классифицируют как силикат. Группа кварца включает различные полиморфные модификации SiO₂, такие как кварц, кристобалит, тридимит, коэсит и стишовит, причём последние две являются фазами высокого давления.

Теоретический химический состав кварца: SiO₂ 100%, или Si 46,74% и O 53,26%. Природный кварц относительно чист, но может содержать следы примесей, таких как Al, K, Na, Li, Ca, Fe, Mg, Mn, Ti, Cu, Zn, Cr, Ni, B, P, обусловленные изоморфным замещением.

Открытая кристаллическая структура кварца SiO₂ обуславливает относительно низкую плотность, равную 2,65. Однако связи Si-O в тетраэдрах [SiO₄] прочны, что обуславливает твёрдость кварца 7 по шкале Мооса. Он устойчив к кислотам (кроме HF), малорастворим в растворе KOH и имеет высокую температуру плавления (1710–1756 °C), при застывании превращаясь в плавленый кварц (кварцевое стекло).

Кварц — твёрдый, износостойкий силикатный минерал со стабильными химическими свойствами. Обычно он бесцветный или молочно-белый, но может иметь различные оттенки из-за примесей. Он полупрозрачен, твёрдость 7, хрупкий раковистый излом, стеклянный блеск и удельный вес 2,65. Он обладает оптической активностью, пьезоэлектрическими свойствами, низкой теплопроводностью, непроводимостью и значительной анизотропией электрических, термических и некоторых механических свойств.

2. Прошлое: семь основных типов кварцевых минеральных ресурсов

Кварц широко распространён в природе и имеет разнообразное происхождение. В настоящее время выделяют семь основных промышленных типов месторождений кварцевого минерала: природный кристалл, кварцевый песчаник, кварцит, жильный кварц, порошкообразный кварц, природный кварцевый песок и гранитный кварц.

Натуральный кристалл

Крупный, бесцветный, прозрачный кристалл кварца, состоящий преимущественно из диоксида кремния. Образуется в полостях, трещинах горных пород, трещинах или разломах в строгих условиях, требующих достаточного пространства, богатых кремнием гидротермальных растворов, определённой температуры/давления и достаточного времени.

Кварцевый песчаник

Консолидированная песчанистая осадочная порода с содержанием кварца и кремнистых обломков, как правило, >95%. Акцессорные минералы часто представлены полевыми шпатами, слюдой и глинистыми минералами, с небольшим количеством тяжёлых минералов. Цемент, как правило, кремнистый.

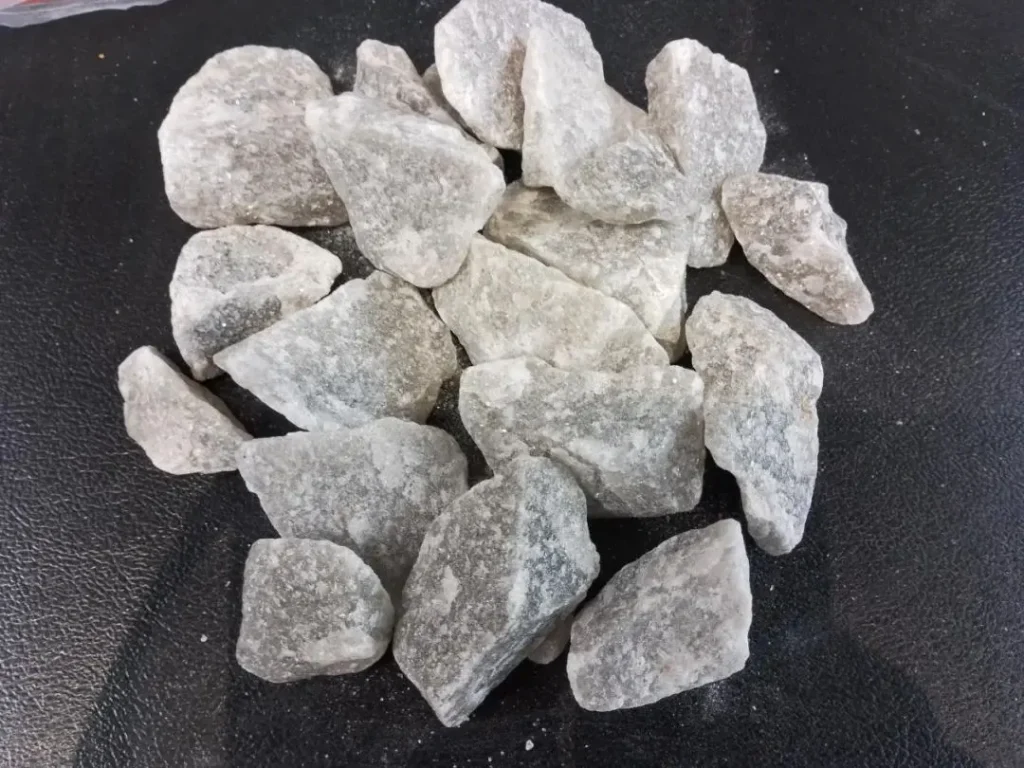

Кварцит

Метаморфическая порода, образовавшаяся из кварцевого песчаника или других кремнистых пород в результате регионального или термического контактного метаморфизма. Сопутствующие минералы могут включать полевые шпаты, слюду, глинистые минералы, а также следы турмалина, гематита и циркона. По сравнению с кварцевым песчаником, он плотнее, твёрже и компактнее.

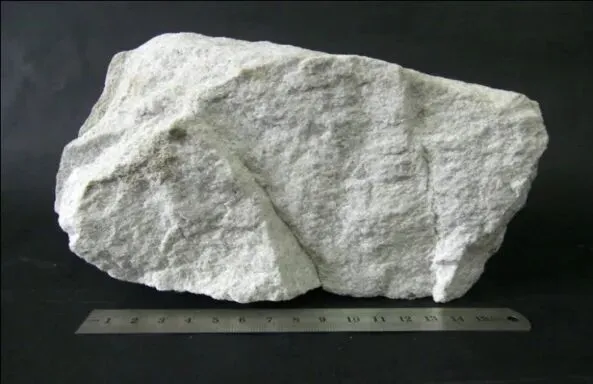

Жильный кварц

Образован преимущественно в результате магмато-гидротермальной деятельности, связанной с гранитом. Имеет массивную структуру, простой минеральный состав (почти полностью кварцевый), содержание SiO₂ обычно превышает 99%. Жильные кварцевые месторождения, как правило, небольшие по масштабам, крутопадающие, мощностью от нескольких метров до десятков метров и длиной от десятков до сотен метров.

Порошкообразный кварц (аммозит)

Природная порошкообразная кварцевая руда с очень мелкими частицами и высоким содержанием SiO₂. Образуется преимущественно из выветренной кремнистой материнской породы, образуя осадочные отложения выветривания. Особые геологические условия, тёплый влажный палеоклимат и мягкий палеорельеф приводят к разрушению кремнистой породы, при этом вода выносит примеси, образуя отложения.

Натуральный кварцевый песок

Кварцевый песчаник – минеральное сырье, образующееся в результате длительного естественного выветривания материнских пород, таких как гранит, кварцит, кварцевый песчаник и жильный кварц. Сопутствующие минералы включают полевой шпат, обломки горных пород, слюду, глинистые минералы и тяжёлые минералы, такие как циркон, турмалин, ильменит и амфибол. В основном морские и озёрные осадочные песчаные отложения.

Гранитный кварц

Основная причина, по которой такие компании, как Sibelco (серия IOTA), добились международной монополии на производство высокочистого кварца, заключается в их уникальном сырье – гранитном кварце из Спрус-Пайн, Северная Каролина, США. Это месторождение кварца имеет легендарную историю открытия.

Кварц, изначально добывавшийся для получения полевого шпата и мусковита, был побочным продуктом. В 1970-х годах, когда ресурсы кварцевого стекла сократились, поиск альтернатив стал актуальным. Благодаря усовершенствованной технологии флотации, кварц из гранитных пегматитов заменил кристалл для производства высокочистого кварцевого песка, и на этом рынке США доминируют и по сей день.

3. Настоящее время: типичные применения кварца

Кварц находит широкое применение. После различных стадий обработки он используется в стекольной, литейной, керамической, огнеупорной, химической промышленности, нефтедобыче, водоочистке, строительстве, производстве новых фотоэлектрических систем, электронных полупроводников, оптического волокна, оптики, источников света, высококачественных волоконных материалов, промышленных наполнителей и многом другом.

Наибольший объем применения

Стекольная промышленность является крупнейшим потребителем кварца, который широко используется в строительстве, автомобилестроении, новой энергетике и медицине. Основная продукция включает листовое, тарное, закаленное, фотоэлектрическое, электронное и фармацевтическое стекло.

В 2021 году объём производства стекла в Китае составил 10,17 млн коробок, на производство которых было израсходовано около 34,06 млн тонн кварцевого песка. Согласно национальным данным, в 2023 году Китай произвел 9,69 млн коробок листового стекла (израсходовав около 32,47 млн тонн кварцевого песка) и 24,78 млн тонн прокатного стекла для фотоэлектрических систем (израсходовав около 17,6 млн тонн кварцевого песка с низким содержанием железа, что составляет около 0,71 т на тонну стекла). Таким образом, только на производство листового и фотоэлектрического стекла в 2023 году было израсходовано более 50 млн тонн кварцевого песка.

Спрос на вторичном рынке обусловлен сферой недвижимости, автомобилестроения, бытовой техники, фотоэлектрических систем, контейнеров для ежедневного использования и электроники. Исторически ~75% был связан с недвижимостью; в будущем спрос на обычное стекло будет расти медленно из-за спада в секторе недвижимости. Благодаря целям «двойного углеродного» сокращения, мировые установки фотоэлектрических систем продолжат расти, поддерживая рост спроса на фотоэлектрическое стекло.

Эффективное измельчение имеет решающее значение для достижения точной тонкости, необходимой на различных этапах производства стекла. Именно здесь незаменима специализированная кварцевая мельница, обеспечивающая равномерное распределение размера частиц для оптимальной плавки и качества продукции.

Приложения самого высокого уровня:

Полупроводники

Основой производства полупроводниковых ИС является производство кристаллов, включающее выращивание монокристаллов, изготовление пластин, производство кристаллов ИС и корпусирование. Наиболее ответственными и трудоёмкими этапами являются изготовление кремниевых пластин и их изготовление. Кварц используется в основном для изготовления кварцевых тиглей полупроводникового качества и вспомогательных материалов при производстве пластин.

Кварцевые изделия используются на всех ключевых этапах обработки кремниевых пластин, таких как диффузия, окисление, осаждение и травление. Высокочистый кварцевый песок с чистотой 5N2 используется для изготовления полупроводниковых кварцевых тиглей, а пески с чистотой 4N и 4N8 используются для производства кварцевых материалов, используемых для окисления и диффузии пластин.

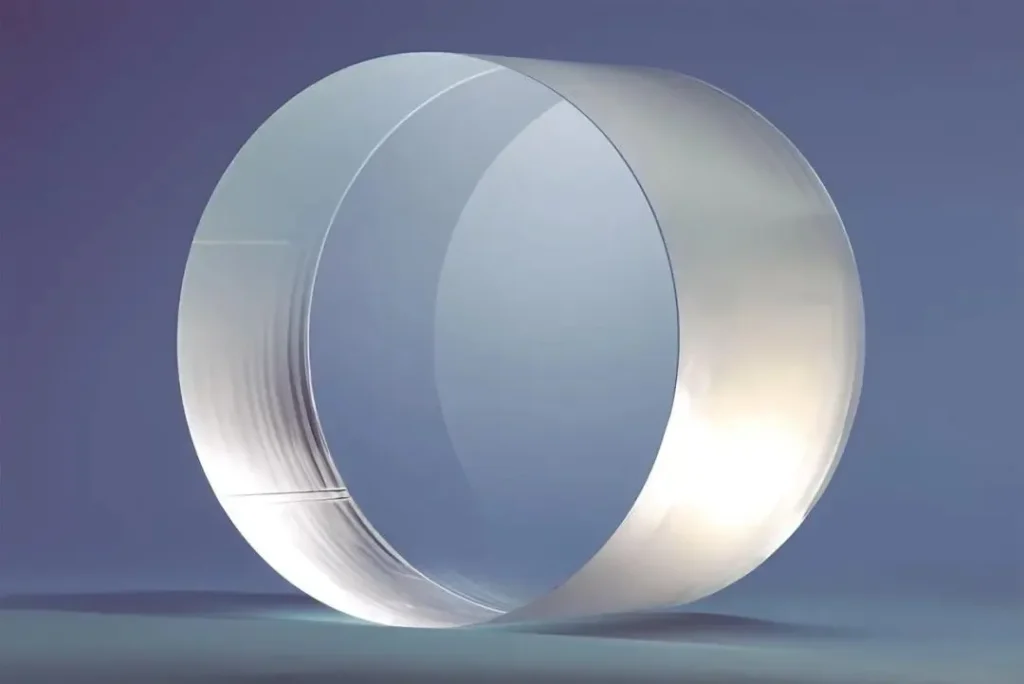

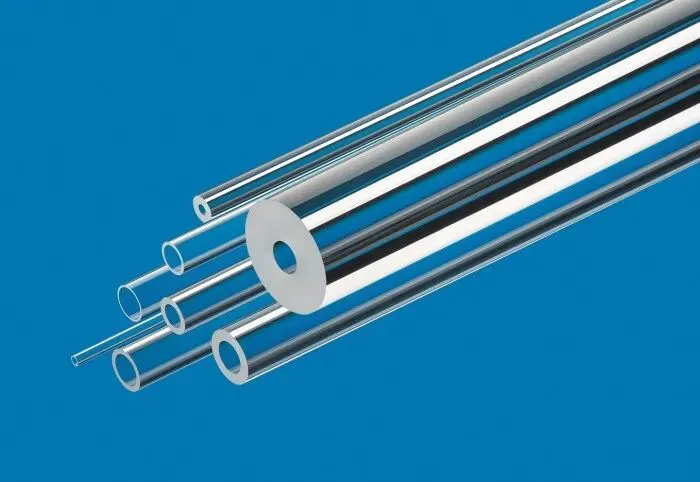

Оптическое волокно

Благодаря масштабному строительству информационных сетей глобальная оптоволоконная связь стремительно развивается. Китай в настоящее время является крупнейшим производителем и потребителем. Заготовки для оптоволокна составляют основу производственной цепочки. Кварцевое стекло для оптоволокна является основополагающим материалом. Кварцевые подложки и оболочки – это высококачественные кварцевые трубки, играющие ключевую роль в подготовке заготовок.

Исследователи из компании Jiuzhi Guangdianzicail Technology Co., Ltd. и Государственной ключевой лаборатории технологий производства оптических волокон и кабелей использовали порошок природного кварца и метод плазменного твердофазного внешнего осаждения (PSOD) для производства крупногабаритных кварцевых оболочек для заготовок одномодовых волокон. Изделия характеризуются одностадийной формовкой, низким содержанием гидроксильных групп, малым количеством примесей, высокими техническими характеристиками и хорошей степенью стеклования, что отвечает требованиям к заготовкам одномодовых волокон. Это открывает новые возможности для создания волокон с низким затуханием и открывает широкие перспективы для создания волокон связи нового поколения со сверхнизкими потерями.

Самые популярные приложения

В последние годы «Новая тройка» — новые энергетические транспортные средства, литиевые батареи и солнечные фотоэлементы — добавила блеска китайскому производству, особенно в экспорте, придав новый импульс высококачественному экономическому развитию.

В цепочке производства фотоэлектрических систем кварцевые изделия играют ключевую роль. Помимо фотоэлектрического стекла, изготовленного из сверхчистого кварцевого песка с низким содержанием железа, кварцевые тигли, изготовленные из высокочистого кварцевого песка, в последнее время являются наиболее заметным продуктом в сфере переработки кварца.

Кварцевые тигли – специализированный продукт из кварцевого стекла – отличаются чистотой, однородностью и устойчивостью к высоким температурам. Они широко используются в производстве кристаллического кремния для солнечной энергетики и полупроводников и являются расходными материалами. По сравнению с обычным кварцевым песком, высокочистый кварцевый песок, полученный методом обогащения, обладает более высокой устойчивостью к высоким температурам и термической стабильностью. Чистота кварцевого песка, используемого в качестве основного материала, является ключевым фактором, обеспечивающим превосходные эксплуатационные характеристики тигля.

Мельница для измельчения кварцевого порошка Epic

Переработка кварца для таких требовательных применений, как производство высокочистого кварцевого песка или наполнителей, требует точного измельчения и классификации. Эпический порошок Специализируется на поставках современных кварцевых мельниц. Мы предлагаем широкий спектр оборудования для измельчения: Воздушные сепараторы и шаровые мельницы, а также струйные мельницыМы можем удовлетворить самые разнообразные требования к производству кварца и других минералов, гарантируя оптимальную тонкость, чистоту и эффективность для ваших конкретных применений. Сотрудничество с Epic Powder гарантирует вам наличие технологий и опыта для обработки различных кварцевых материалов и достижения желаемых производственных результатов. Свяжитесь с нами сегодня, чтобы заказать кварцевую мельницу, изготовленную по индивидуальному заказу.