Thạch anh tinh khiết cao là một loại khoáng chất phi kim loại quan trọng và có nhu cầu cao. Nó có các đặc tính chịu nhiệt độ cao, chống ăn mòn, ổn định nhiệt và cách điện. Nó được sử dụng rộng rãi trong các nguồn sáng điện cao cấp, mạch tích hợp quy mô lớn và siêu lớn, quang điện mặt trời, sợi quang, hàng không vũ trụ và công nghiệp quân sự. Do tầm quan trọng chiến lược của các lĩnh vực này đối với sự phát triển lâu dài của quốc gia, thạch anh tinh khiết cao được xếp vào loại vật liệu công nghệ cao và được các chính phủ trên toàn thế giới bảo vệ nghiêm ngặt. Ngay từ năm 2010, Liên minh châu Âu đã liệt kê nó là một nguyên liệu thô quan trọng. Hiện nay, chỉ có một số ít công ty trên toàn cầu có khả năng sản xuất loại thạch anh này một cách chính hãng.

Bảng 1 Thị trường ứng dụng của thạch anh tinh khiết cao

| Độ tinh khiết (Hàm lượng SiO₂) | >99.99% | >99.997% | >99.999% |

|---|---|---|---|

| Sản phẩm chính | Ống đèn chịu nhiệt cao, ống thạch anh nung chảy, thủy tinh thạch anh, bột silica, thiết bị quang học, thủy tinh quang học thạch anh đặc biệt, v.v. | Nồi nấu silicon đơn tinh thể, nồi nấu silicon đa tinh thể, thủy tinh thạch anh chất lượng cao và các sản phẩm từ thạch anh, sợi quang và các linh kiện quang điện tử liên quan, v.v. | Nồi nung Czochralski (CZ), thủy tinh thạch anh siêu tinh khiết dùng cho chất bán dẫn, nồi nung thạch anh cao cấp dùng cho chất bán dẫn. |

| Ứng dụng trong ngành công nghiệp Giá (USD/tấn) | 600 ~ 1500 | 5,500 ~ 8,500 | 12,000 ~ 15,000 |

Thông số kỹ thuật của thạch anh tinh khiết cao

Không có định nghĩa nào được chấp nhận rộng rãi. Müller A. và cộng sự (2007) là những người đầu tiên cố gắng phân loại thạch anh dựa trên hàm lượng các nguyên tố tạp chất vi lượng, cho rằng thạch anh có độ tinh khiết cao cần đáp ứng các tiêu chí (ppm): Al < 30, B < 1, Ca < 5, Fe < 3, K < 8, Li < 5, Na < 8, Ti < 10, P < 2, với tổng tạp chất < 50 ppm. Zhang Ye và cộng sự (2010) lưu ý rằng cát thạch anh có độ tinh khiết cao được quốc tế công nhận có tổng hàm lượng 15 tạp chất (Al, K, Na, Li, Ca, Fe, Mg, Mn, Ti, Zr, Cu, Cr, Ni, P, B) nhỏ hơn 22,26 ppm. “Hướng dẫn trình diễn ứng dụng đợt đầu cho các vật liệu mới quan trọng (phiên bản 2018)” của Trung Quốc quy định thạch anh có độ tinh khiết cao phải có tổng hàm lượng 12 tạp chất (Fe, Mg, Cr, Ni, Cu, Mn, Ca, Al, Na, Li, K, B) nhỏ hơn 6 ppm.

Các bao thể chất lỏng, thường gặp trong thạch anh, là nguyên nhân chính gây ra bọt khí trong các sản phẩm thạch anh có độ tinh khiết cao, ảnh hưởng nghiêm trọng đến chất lượng. Do đó, thạch anh có độ tinh khiết cao phải không chứa hoặc chứa rất ít bao thể chất lỏng. Quan sát cho thấy nó cần đáp ứng các tiêu chí sau: tỷ lệ diện tích bao thể chất lỏng trên mỗi hạt <1%; dưới kính hiển vi (vật kính 10X, kích thước hạt trung bình 0,1mm), các hạt chứa bao thể chất lỏng <1%; tổn thất khối lượng do nhiệt <15 ppm.

Bảng 2 Các chỉ số của dòng thạch anh tinh khiết cao US Unimin IOTA (ppm) [9]

| Yếu tố | Al | B | Ca | Cr | Đồng | Sắt | K | Li | Mg | Mn | Na | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IOTA – Tiêu chuẩn | 16.2 | 0.08 | 0.5 | <0,05 | <0,05 | 0.23 | 0.60 | 0.90 | <0,05 | <0,05 | 0.9 | <0,05 |

| IOTA – 4 | 8.0 | 0.04 | 0.6 | <0,05 | <0,05 | 0.3 | 0.35 | 0.15 | <0,05 | <0,05 | 0.9 | <0,05 |

| IOTA – 6 | 8.0 | 0.04 | 0.6 | <0,05 | <0,05 | 0.15 | 0.07 | 0.15 | <0,05 | <0,05 | 0.08 | <0,05 |

| IOTA – 8 | 7.0 | <0,04 | 0.5 | <0,02 | <0,02 | <0,03 | <0,04 | <0,02 | <0,02 | <0,02 | – | <0,02 |

Lưu ý: Dấu “-” biểu thị dữ liệu không được báo cáo trong tài liệu.

Nguyên liệu thạch anh tinh khiết cao

Ban đầu, người ta sử dụng tinh thể tự nhiên (loại I & II). Với sự phát triển nhanh chóng của ngành công nghiệp công nghệ cao, nguồn tinh thể tự nhiên hạn chế và đang cạn kiệt không đáp ứng được nhu cầu. Từ những năm 1970, Mỹ sử dụng pegmatit granit, Nhật Bản sử dụng pegmatit hạt mịn, trong khi Nga và Đức sử dụng thạch anh biến chất và thạch anh mạch. Hiện nay, khoáng chất thạch anh tự nhiên là nguồn cung cấp chính.

Đặc điểm khoáng vật học của nguyên liệu thạch anh tinh khiết cao

Chất lượng của thạch anh tinh khiết cao không chỉ đơn thuần tỷ lệ nghịch với hàm lượng tạp chất trong nguyên liệu thô, mà còn liên quan mật thiết đến... khả năng xử lý Hàm lượng tạp chất được xác định bởi thành phần khoáng vật trong quá trình chế biến. Các loại quặng thạch anh khác nhau có đặc điểm khoáng vật riêng biệt. Phân tích chi tiết là điều cơ bản để xác định các đặc tính của quặng, thiết kế các quy trình làm giàu/tinh chế và đặt ra các mục tiêu sản phẩm.

1. Thành phần hóa học và sự xuất hiện của các nguyên tố tạp chất

Phân tích hóa học cho biết loại và hàm lượng các nguyên tố nhưng không thể đánh giá chính xác khả năng chế biến thành thạch anh có độ tinh khiết cao. Tạp chất rất đa dạng về loại, hàm lượng và vị trí (xem Bảng 3 để biết các dạng phổ biến).

Bảng 3 Các trạng thái xuất hiện phổ biến của các nguyên tố tạp chất trong nguyên liệu thạch anh [1,12]

| Yếu tố | Trạng thái xảy ra | Hình thức hiện có | Yếu tố | Trạng thái xảy ra | Hình thức hiện có |

|---|---|---|---|---|---|

| Al | Đồng hình Khoáng sản độc lập | Các khuyết tật mạng tinh thể trong thạch anh, mica, feldspar, khoáng sét | Ti | Đồng hình Khoáng sản độc lập | Các khuyết tật mạng tinh thể trong thạch anh, rutile |

| Sắt | Đồng hình Khoáng sản độc lập | Các khuyết tật mạng tinh thể trong thạch anh, oxit sắt, các tạp chất khoáng rắn. | Ge | Đồng hình Khuyết điểm | Các khuyết tật mạng tinh thể trong thạch anh |

| Li | Đồng hình Bao gồm | Các khuyết tật mạng tinh thể trong thạch anh, pha lỏng trong các bao thể chất lỏng | Mg | Đồng hình Bao gồm | Tinh thể thạch anh, tạp chất mica |

| K | Đồng hình Bao gồm | Các khuyết tật mạng tinh thể trong thạch anh, mica, khoáng sét, pha lỏng trong các bao thể chất lỏng | Ca | Bao thể khoáng chất độc lập | Các khoáng chất như fluorit, pha lỏng trong các bao thể chất lỏng. |

| Na | Đồng hình Bao gồm | Các khuyết tật mạng tinh thể trong thạch anh, tạp chất mica, pha lỏng trong các bao thể chất lỏng | -Ồ | Đồng hình Khuyết điểm | Các khuyết tật mạng tinh thể trong thạch anh |

2. Thành phần khoáng chất và kết cấu

Để lựa chọn nguyên liệu thô phù hợp và thiết kế quy trình tinh chế tối ưu, cần xác định... phương thức xảy ra Việc loại bỏ tạp chất là rất quan trọng. Các khoáng chất đi kèm độc lập (ví dụ: mica, feldspar, hematit, tourmaline, chlorit, khoáng sét) là những chất mang tạp chất chính và dễ dàng tạo thành các bao thể khoáng chất trong quá trình khoáng hóa, ảnh hưởng đáng kể đến chất lượng sản phẩm cuối cùng. Cấu trúc xen kẽ giữa thạch anh và khoáng chất đi kèm ảnh hưởng trực tiếp đến mức độ giải phóng và do đó ảnh hưởng đến hiệu quả tinh chế. Sự biến đổi địa chất/biến chất mạnh hơn dẫn đến sự khác biệt rõ rệt hơn về cấu trúc xen kẽ, phát triển từ dạng liền kề sang dạng khâu nối hoặc thậm chí dạng bao bọc, làm tăng độ khó giải phóng và giảm tiềm năng xử lý.

- Hình 1(a): Pegmatit granit từ Spruce Pine, Hoa Kỳ — khoáng vật học phức tạp nhưng thạch anh dễ dàng tách ra, chứa rất ít tạp chất.

- Hình 1(b): Thạch anh dạng mạch từ Thanh Hải, Trung Quốc—hạt thô, tinh khiết với một lượng nhỏ muscovit ở ranh giới/mép hạt, dễ dàng tách ra, có thể thu được >99,99% SiO₂, Al <10 ppm sau khi xử lý.

- Hình 1(c): Tinh quặng đã tinh chế cho thấy các tạp chất khoáng chất tồn tại dai dẳng — với công nghệ hiện tại, các tạp chất bị giữ lại ở trong Các hạt thạch anh không thể được tách biệt hiệu quả. Thạch anh có độ giải phóng khoáng chất kém và chứa nhiều tạp chất rất khó chế biến thành thạch anh có độ tinh khiết cao.

3 Bao thể chất lỏng

Có mặt khắp nơi trong khoáng vật/đá (10²–10⁹ trên cm³, thường <50 µm). Loại, kích thước và hàm lượng của chúng ảnh hưởng đáng kể đến chất lượng. Được phân loại theo thành phần: khí, lỏng, khí-lỏng, ba pha. Chúng chứa các tạp chất (Na, K, Ca, v.v.) và ảnh hưởng tiêu cực nghiêm trọng đến quá trình nóng chảy. Các nghiên cứu cho thấy việc loại bỏ các bao thể chất lỏng khó hơn việc loại bỏ các tạp chất nguyên tố và là một yếu tố hạn chế quan trọng. Việc lựa chọn thạch anh có ít hoặc không có bao thể chất lỏng là rất quan trọng.

4. Tạp chất mạng tinh thể

Các nguyên tố thay thế cho Si⁴⁺ trong quá trình hình thành tinh thể trở thành tạp chất cấu trúc. Mặc dù hàm lượng thấp, chúng cực kỳ khó loại bỏ và là yếu tố quan trọng nhất hạn chế chất lượng. Các kiểu thay thế: 1) Thay thế đồng hóa trị (Ti⁴⁺, Ge⁴⁺); 2) Thay thế kết hợp (Al³⁺ + P⁵⁺ cho 2Si⁴⁺); 3) Thay thế bù trừ điện tích (Al³⁺, Fe³⁺ cho Si⁴⁺ được cân bằng bởi Li⁺, Na⁺, K⁺, H⁺). Hàm lượng Al thường cao nhất. Sự thay thế của nó tạo ra sự mất cân bằng điện tích, thường tương quan với hàm lượng Li, K, Na cao hơn. Hàm lượng Al có thể cho biết chất lượng nguyên liệu thô. Với công nghệ hiện tại, các tạp chất trong mạng tinh thể hầu như không thể loại bỏ được.

Hình 2 cho thấy kết quả phân tích SEM-EDS của một hạt thạch anh dạng mạch sau quá trình xử lý nhiệt áp suất. Al được phân bố đều (Hình 2b), phù hợp với hình dạng hạt, cho thấy Al liên kết với mạng tinh thể. Sự phân bố Mg không rõ ràng (Hình 2c). Phân tích GFAAS/AAS cho thấy Al = 13,92 ppm, Mg = 0,59 ppm sau quá trình xử lý, cho thấy sự khó khăn cực độ trong việc loại bỏ Al liên kết với mạng tinh thể.

Các khảo sát toàn cầu chỉ ra rằng thạch anh tự nhiên có thể chế biến được phải đáp ứng các tiêu chí sau: hạt có độ tinh khiết hóa học cao, ít/không có tạp chất mạng tinh thể, kích thước hạt lớn, ít tạp chất khoáng/chất lỏng và hàm lượng khoáng chất đi kèm thấp.

Nguyên liệu thạch anh tinh khiết cao điển hình

Mặc dù thạch anh rất dồi dào, nhưng nguyên liệu thô có độ tinh khiết cao chỉ hình thành trong những điều kiện địa chất cụ thể. Rất ít mỏ phù hợp, với quy trình chế biến cực kỳ phức tạp. Dựa trên nguồn gốc: magma, biến chất, thủy nhiệt (xem Bảng 4 để biết đặc điểm/ví dụ).

Ví dụ điển hình là mỏ pegmatit granit Spruce Pine (Mỹ), được hình thành dưới quá trình biến chất tướng lục Alleghanian thúc đẩy sự tái kết tinh năng động, biến dạng dẻo và sự di chuyển tạp chất đến các ranh giới hạt mới thông qua chất lỏng, dẫn đến thạch anh có độ tinh khiết cao với ít tạp chất.

Thạch anh pegmatit magma kết tinh chậm từ magma nhiệt độ cao, cho phép tách tạp chất, tạo ra sản phẩm có độ tinh khiết cao và ít bao thể chất lỏng.

Bảng 4 Đặc điểm của thạch anh thuộc các loại di truyền khác nhau và các ví dụ ứng dụng điển hình [18]

| Các loại thạch anh có nguồn gốc di truyền khác nhau | Đặc trưng | Ví dụ ứng dụng điển hình |

|---|---|---|

| Loại magma | Thạch anh granit | Nhiệt độ hình thành (700 °C – 1.000 °C), các hạt thạch anh tinh khiết và hầu như không có bao thể chất lỏng. |

| Loại biến chất | Thạch anh biến chất cao cấp | Nhiệt độ hình thành (750 – 900 °C), hàm lượng bao thể chất lỏng thấp. |

| Thạch anh biến chất | Thời gian hình thành càng lâu và các sự kiện nhiệt càng dữ dội thì thạch anh càng tinh khiết và càng ít tạp chất lỏng. | |

| Loại tăng trưởng thủy nhiệt | Thạch anh pegmatit giai đoạn đầu | Nhiệt độ hình thành 600 – 700 °C, kích thước hạt thường từ 2 – 6 mm, trong suốt, tinh thể đơn nguyên chất, ít bao thể chất lỏng. |

| Tinh thể pegmatit giai đoạn giữa đến cuối | Nhiệt độ hình thành: 500 – 600 °C. | |

| Thạch anh mạch nhiệt dịch | Nhiệt độ hình thành 400 – 500 °C, trong suốt – bán trong suốt, hàm lượng bao thể chất lỏng tương đối thấp. | |

| Thạch anh mạch nhiệt dịch | Nhiệt độ hình thành 50 – 400 °C, màu trắng – trắng sữa, chứa một lượng lớn các bao thể chất lỏng nhỏ li ti. |

Việc lựa chọn nguyên liệu thô phù hợp đòi hỏi phải nghiên cứu khoáng vật học chi tiết bằng nhiều kỹ thuật khác nhau, tập trung vào: 1) Cấu trúc và hàm lượng tạp chất khoáng; 2) Hàm lượng tạp chất lỏng; 3) Hàm lượng tạp chất mạng tinh thể.

Công nghệ xử lý thạch anh tinh khiết cao

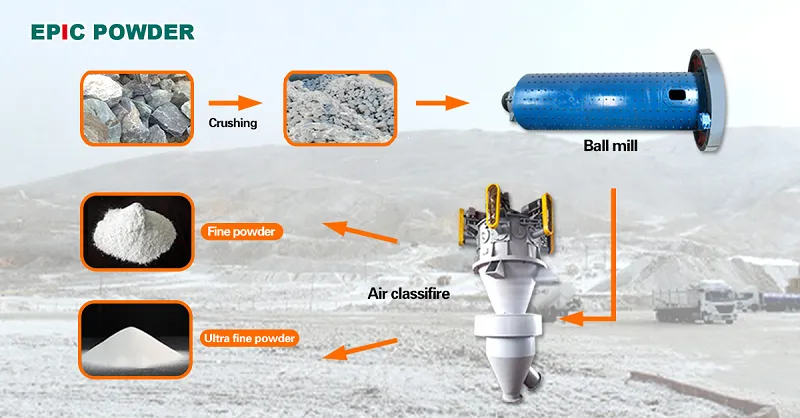

Mục tiêu là tách các tạp chất khác nhau. Các bước: 1) Nghiền nhỏ và phân loại để tách thạch anh khỏi tạp chất và đạt được kích thước mục tiêu; 2) Các kỹ thuật chuyên biệt để tách các khoáng chất độc lập, các tạp chất và các tạp chất mạng tinh thể.

1. Xử lý sơ bộ bằng phương pháp nghiền và phân loại

Mục tiêu là giải phóng hiệu quả các tạp chất lỏng và cung cấp nguyên liệu đầu vào có kích thước phù hợp. Để tránh nhiễm bẩn sắt, hãy sử dụng ZrO₂ hoặc vật liệu lọc mã não. Nghiền nhiệt (Nung nóng rồi làm nguội nhanh) làm giảm độ cứng/năng lượng, giảm thiểu ô nhiễm và tạo ra các vết nứt nhỏ giúp tinh chế hóa học. Phân mảnh xung điện áp cao Sử dụng sóng xung kích để phá vỡ thạch anh dọc theo các ranh giới hạt giàu tạp chất.

2. Tách các khoáng chất độc lập liên kết

Các phương pháp hiệu quả bao gồm phân loại theo màu sắc, chà rửa, tách bằng trọng lực, tách từ, Và tuyển nổi (xem Bảng 5).

Bảng 5 Công nghệ tách khoáng chất độc lập liên kết và thạch anh [23-25]

| Phương pháp tách | Nguyên tắc | Các tạp chất chính đã được loại bỏ | Đặc trưng |

|---|---|---|---|

| Phân loại màu sắc | Tính chất quang học của khoáng vật | Các khoáng chất tạp chất có màu sẫm, thạch anh trắng đục, v.v. | Rất hiệu quả đối với các hạt thô. |

| Chà rửa | Ma sát giữa các hạt khoáng chất | Lớp bùn mịn và màng oxit bám dính trên bề mặt các hạt thạch anh. | Làm sạch bằng cơ học, làm sạch bằng hóa chất, làm sạch bằng sóng siêu âm. |

| Phân tách bằng trọng lực | Mật độ khoáng chất | Mica, zircon, rutile, v.v. Hematit, magnetit, tourmaline, mica và các khoáng vật từ tính khác. | Thiệt hại đáng kể về chất cô đặc. |

| Tách từ | Từ tính khoáng vật | Phân tách từ tính cường độ cao nhiều giai đoạn. | |

| Tuyển nổi | Tính chất bề mặt khoáng chất | Mica, fenspat, apatit, v.v. | Tuyển nổi ngược, nhiều giai đoạn làm sạch. |

Quá trình tuyển từ đa tầng cường độ cao loại bỏ các khoáng chất và tạp chất từ tính. Tuyển nổi tách các khoáng chất silicat như mica và feldspar. Nhiều giai đoạn làm sạch là rất cần thiết. Thường cần kết hợp các sơ đồ quy trình dựa trên đặc điểm của quặng.

Sau quá trình tiền xử lý và tách vật lý, hàm lượng SiO₂ có thể đạt tới ~99,9%, nhưng không đạt tiêu chuẩn độ tinh khiết cao, vì các phương pháp này không hiệu quả đối với các tạp chất trong mạng tinh thể.

3. Tách các tạp chất bao gồm

3.1 Quá trình hòa tan khoáng chất trong các tạp chất bằng hỗn hợp axit

Phương pháp này chỉ tận dụng khả năng hòa tan của thạch anh trong HF, trong khi các tạp chất khoáng khác hòa tan trong các axit (H₂SO₄, HCl, HNO₃, HF). Hỗn hợp axit là hiệu quả nhất đối với các tạp chất phức tạp. Các nghiên cứu nhiệt động học (Bảng 6) cho thấy các tạp chất phổ biến. Có thể Chúng hòa tan trong axit chứa HF, nhưng tốc độ phản ứng chậm (hằng số cân bằng ~1,0–1,5).

Bảng 6 Năng lượng tự do Gibbs của phản ứng phân hủy và hằng số cân bằng của các tạp chất khoáng phổ biến trong thạch anh trong hỗn hợp axit chứa HF ở các nhiệt độ khác nhau [13]

| Nhiệt độ/°C | 25 | 75 | 100 | 150 | 175 | 200 | 225 |

|---|---|---|---|---|---|---|---|

| Feldspar kali ΔrGT | –403.2 | –451,86 | -474,98 | –517,36 | -536,08 | -548,97 | -583,72 |

| K | 1.18 | 1.17 | 1.17 | 1.16 | 1.15 | 1.15 | 1.15 |

| Albite ΔrGT | –409,22 | –455,41 | –477,36 | -517,61 | –535,37 | –547,16 | –581,23 |

| K | 1.18 | 1.17 | 1.18 | 1.16 | 1.15 | 1.15 | 1.15 |

| Anorthit ΔrGT | -539,45 | -571,71 | –586,77 | -614,89 | -628,75 | –635,14 | -660,45 |

| K | 1.24 | 1.22 | 1.21 | 1.19 | 1.18 | 1.18 | 1.17 |

| Diopside ΔrGT | –676,42 | –663,01 | –637,67 | –619,14 | -595,78 | -556,82 | -556,92 |

| K | 1.31 | 1.26 | 1.23 | 1.19 | 1.17 | 1.16 | 1.14 |

| người Muscovite ΔrGT | -704,97 | -768,97 | -799,71 | –858,27 | –886,61 | -905,49 | -954,7 |

| K | 1.33 | 1.3 | 1.29 | 1.28 | 1.27 | 1.27 | 1.26 |

| Spodumene ΔrGT | –1015,6 | –1060,2 | –1078,3 | –1108,4 | –1123 | –1124,5 | –1145.1 |

| K | 1.51 | 1.44 | 1.42 | 1.37 | 1.35 | 1.33 | 1.32 |

| Hematit ΔrGT | -86,59 | -80,44 | –77,14 | -72,39 | -72,92 | -68,75 | -67,38 |

| K | 1.04 | 1.03 | 1.03 | 1.02 | 1.02 | 1.02 | 1.02 |

| FeO ΔrGT | –111,77 | –110,56 | -110,09 | -103,65 | -105,58 | –105,2 | -106,15 |

| K | 1.05 | 1.04 | 1.04 | 1.03 | 1.03 | 1.03 | 1.03 |

| Nam châm ΔrGT | –179,71 | –172,36 | -168,59 | –164,2 | –166,58 | -161,95 | –161,44 |

| K | 1.08 | 1.06 | 1.06 | 1.05 | 1.05 | 1.04 | 1.04 |

| Pyrit ΔrGT | –161,69 | –187,38 | –203,87 | –241,16 | –260,4 | -285,45 | –307,56 |

| K | 1.07 | 1.07 | 1.07 | 1.07 | 1.07 | 1.08 | 1.08 |

Tiếp xúc hiệu quả Việc bao gồm các nội dung là điều kiện tiên quyết. Xử lý nhiệt chuyển pha (Nung nóng đến khoảng 573°C để chuyển pha α-β hoặc 1470°C đối với cristobalite, sau đó làm nguội nhanh) sử dụng sự giãn nở thể tích để tạo ra các vết nứt, làm lộ các tạp chất. Nhược điểm: có thể bị thủy tinh hóa ở nhiệt độ cao, hình thành các oxit/nitrit bền vững.

3.2 Sự vỡ bao thể chất lỏng ở nhiệt độ cao

Quá trình gia nhiệt khiến áp suất bên trong vượt quá giới hạn chịu đựng, làm vỡ các bao thể và giải phóng tạp chất để rửa bằng axit sau đó. Không phải tất cả đều vỡ: các bao thể giàu chất lỏng vỡ gần nhiệt độ đồng nhất hóa; các bao thể giàu hơi có thể chịu được nhiệt độ cao hơn. Mô hình nhiệt động học (Bảng 7) cho thấy áp suất bên trong cao hơn đối với các bao thể được đồng nhất hóa bằng chất lỏng so với các bao thể được đồng nhất hóa bằng hơi ở cùng nhiệt độ.

3.3 Clo hóa (Bay hơi clorua)

Việc nung nóng thạch anh đến 1000–1500°C dưới tác dụng của Cl₂, HCl hoặc hỗn hợp khí sẽ làm bay hơi các tạp chất kim loại dưới dạng clorua và giúp loại bỏ các bao thể chất lỏng/nhóm hydroxyl. Độ dốc thế năng hóa học thúc đẩy sự khuếch tán của bao thể. Nghiên cứu (ví dụ: Mao Lingwen và cộng sự) cho thấy nồng độ [OH⁻] giảm từ 35 ppm xuống 20,5 ppm ở 1250°C trong môi trường Cl₂.

Loại bỏ tạp chất mạng tinh thể

Quá trình này bao gồm việc phá vỡ các liên kết Me-O được tạo ra thông qua phản ứng thế. Năng lượng liên kết thay đổi (xem Bảng 8):

Bảng 8 Năng lượng liên kết của các liên kết Me–O trong silicat [13]

| Tôi | Si⁴⁺ | Mn²⁺ | Cu²⁺ | Ca²⁺ | Mn²⁺ | Pb²⁺ | Ti⁴⁺ |

| Năng lượng liên kết (KJ/mol) | 10.312 – 13.146 | 3,745 | 3,598 | 3,510 | 3,816 | 3,469 | 12,058 |

| Tôi | Al³⁺ | Zn²⁺ | Fe³⁺ | Li⁺ | Na⁺ | K⁺ | Ba²⁺ |

| Năng lượng liên kết (KJ/mol) | 7.201 – 7.858 | 3,037 | 3,845 | 1,469 | 1,347 | 1,251 | 3,213 |

Các liên kết kim loại kiềm (Li, Na, K)-O yếu nhất nhưng khó loại bỏ do vai trò cân bằng điện tích. Các liên kết Fe, Cu, Ca, Mn-O dễ loại bỏ hơn. Các liên kết Al, Ti-O mạnh nhất, khiến Al và Ti trở thành những tạp chất mạng tinh thể khó loại bỏ nhất.

Trong quá trình biến đổi cấu trúc tinh thể (ví dụ: thạch anh → cristobalite ở ~1500°C), các liên kết bị phá vỡ/tái tạo, mạng tinh thể giãn nở (trục c: 5,404Å → 6,971Å), có khả năng tạo điều kiện cho sự di chuyển của tạp chất lên bề mặt. Môi trường N₂ có thể thúc đẩy quá trình chuyển đổi cao hơn so với chân không.

Dưới điểm nóng chảy của thạch anh, các tạp chất phản ứng với các chất clo hóa (HCl, NH₄Cl, Cl₂) để tạo thành các clorua dễ bay hơi. Sự chuyển pha đi kèm có thể hỗ trợ sự di chuyển của tạp chất lên bề mặt để phản ứng và ngăn ngừa sự tái kết hợp khi làm nguội.

Tác giả: Ma Chao: Đặc điểm khoáng vật học và những tiến bộ công nghệ chế biến nguyên liệu thạch anh tinh khiết cao, bảo vệ và sử dụng tài nguyên khoáng sản.

Bột Epic

Bột Epic là nhà cung cấp chuyên nghiệp về xử lý bột. các dự ánĐặc biệt là các công đoạn nghiền bột, phân loại bột, phân tán bột, xử lý bề mặt bột và tái chế chất thải. Chúng tôi cung cấp dịch vụ tư vấn, thử nghiệm, thiết kế dự án, máy móc, vận hành và đào tạo.

Cảm ơn bạn đã đọc. Vui lòng để lại bình luận bên dưới. Bạn cũng có thể liên hệ với đại diện chăm sóc khách hàng trực tuyến của EPIC Powder. Zelda Nếu có bất kỳ thắc mắc nào khác, vui lòng liên hệ.