1. Overzicht van Attapulgiet

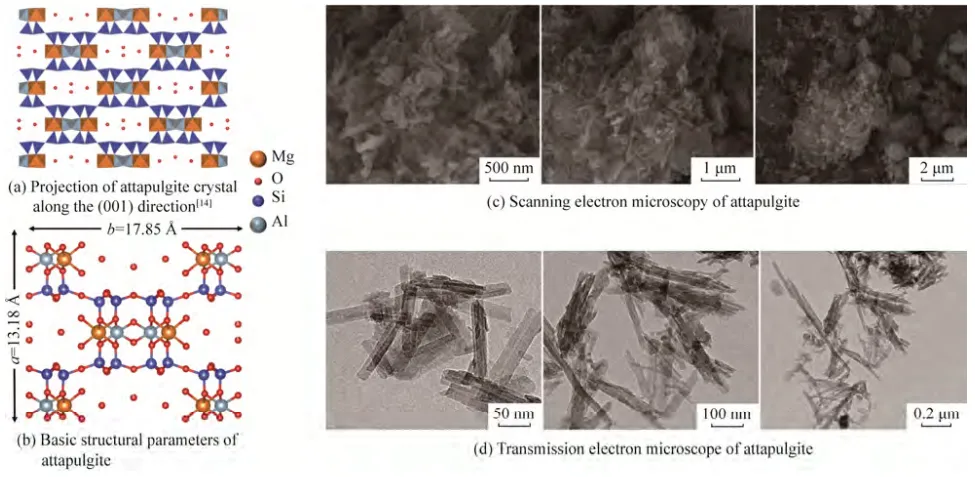

Attapulgiet (Mg₅Si₈O₂₀(OH)₂·4H₂O) is een kleimineraal met een nanostaafvormige kristalmorfologie. De lengte is ongeveer 0,5-5 μm, de diameter is ongeveer 20-70 nm, met regelmatige nanoschaalkanalen van 0,37 nm × 0,64 nm. Het is een waterhoudend magnesiumaluminiumsilicaat kleimineraal met een gelaagde ketenstructuur. Epic Powder Machinery is gespecialiseerd in straalverpulveringstechnologie. De straalmolen MQW40 van Epic Powder zorgt voor de efficiënte verwerking van attapulgietpoederverpulvering.

Attapulgiet bezit een groot specifiek oppervlak, een grote oppervlaktelading en een groot kationenuitwisselingsvermogen. Hierdoor wordt het veel gebruikt bij de bereiding van adsorbentia, kleefstoffen, droogmiddelen, katalysatoren, levensmiddelenadditieven en functionele composieten. Het speelt een onvervangbare rol als basismateriaal in sectoren zoals chemische technologie, katalyse, milieubescherming en nieuwe materialen. Het verpulveren van attapulgiet is een cruciale voorbehandelingsstap gericht op het vergroten van het specifieke oppervlak om de adsorptiecapaciteit te verbeteren.

Basisstructuurparameters, beelden van een scanning elektronenmicroscoop (SEM).

Transmissie-elektronenmicroscoop (TEM)-beelden.

2. Fysisch-chemische eigenschappen en oppervlaktemodificatie van attapulgiet

2.1 Adsorptie

De aanzienlijke kanaaldoorsnede en unieke kristalstructuur van attapulgiet dragen bij aan de adsorptie-eigenschappen. De adsorptiemechanismen omvatten voornamelijk fysische en chemische adsorptie. Fysische adsorptie vindt plaats via vanderwaalskrachten. Chemische adsorptie vormt covalente bindingen wanneer Si-O-Si-zuurstofbruggen breken, waardoor adsorptiemoleculen zich kunnen hechten. Oppervlaktemodificatie van attapulgiet kan de adsorptieprestaties verbeteren.

Attapulgiet verwijdert effectief onzuiverheden zoals metalen, zwavel en asfalt uit petroleumkoolwaterstoffen, evenals kleur- en schadelijke componenten uit vetten, minerale oliën en plantaardige oliën. Het heeft ook uitstekende adsorptiemogelijkheden voor zware metalen (bijv. Cr³⁺, Hg²⁺). Het wordt veel gebruikt als deodorant, filterhulpmiddel, zuiveraar en ontkleuringsmiddel in de milieubeschermingsindustrie. Het proces van attapulgietverpulvering omvat doorgaans mechanisch breken en vermalen om de gewenste deeltjesgrootteverdeling te bereiken.

2.2 Katalyse

Als natuurlijk voorkomend nanomateriaal met een nanokanaalstructuur bevat attapulgiet nanodeeltjes en een hoge aspectverhouding. Het biedt talrijke nanokanaaltjes en actieve centra. Daardoor kan het zowel als katalysator als katalysatordrager functioneren.

2.3 Colloïdale en suspenderende eigenschappen

Onder invloed van schuifkrachten kan attapulgiet zich verspreiden tot een chaotische driedimensionale netwerkstructuur in water en andere media. Bij lagere concentraties vertonen attapulgietcolloïden een hoge viscositeit en behouden ze een hoge mate van suspensiestabiliteit in zoutoplossingen, naast een goede zout- en alkalibestendigheid, thermische stabiliteit en reologische eigenschappen. Het wordt daarom gebruikt als circulerende boorspoeling in olievelden en als additief in coatings.

2.4 Andere eigenschappen

Attapulgiet heeft een zeer groot specifiek oppervlak en een zekere ionenuitwisselingscapaciteit, waardoor het veel gebruikt wordt als droogmiddel, vochtabsorberend middel, adsorbens, katalysatordrager en antimicrobieel middel. Door de speciale naaldachtige en vezelachtige kristalstructuur is het niet-giftig, geurloos, niet-irriterend, chemisch stabiel, gemakkelijk te drogen en heeft het een lage hardheid, waardoor attapulgiet een uitstekende vulstof is voor polymeermaterialen. Effectieve attapulgietverpulvering kan de staafvormige kristalbundels gedeeltelijk breken, waardoor meer actieve plaatsen vrijkomen.

2.5 Modificatie van Attapulgiet

De unieke structuur en eigenschappen van attapulgiet bieden aanzienlijke toepassingswaarde. De kristalstructuur beperkt echter de adsorptieprestaties. Daarom is na zuivering van attapulgiet oppervlaktemodificatie noodzakelijk om het specifieke oppervlak, de oppervlaktelading en de kanaalgrootte verder te vergroten en zo de adsorptie- en ondersteuningseigenschappen te verbeteren.

Modificatiemethoden voor Attapulgiet

| Modificatiemethode | Primair principe | Toepassingsrichting |

| Thermische behandeling | Attapulgiet verliest geadsorbeerd, zeolitisch, kristallijn en structureel water bij verhitting. Het specifieke oppervlak neemt toe en de diameter van de nanokanalen wordt groter, waardoor de adsorptieprestaties verbeteren. | Vulmaterialen, warmtebehandeling |

| Zuurmodificatie | Zuurbehandeling vervangt kationen in de structuur; octaëdrische kationen lossen op en worden vervangen door waterstofionen; er ontstaan verbroken verbindingen, waardoor het specifieke oppervlak en de activiteit toenemen. | Waterbehandeling, ontkleuringsmiddelen |

| Alkali-modificatie | Door de alkalibehandeling verandert de kristalstructuur, wat een transformatie veroorzaakt. Metaalkationen corroderen, waardoor de negatieve oppervlaktelading en de actieve plekken toenemen. Nanokanalen worden breder en het specifieke oppervlak neemt toe. | Waterbehandeling, ionenadsorptie |

| Zoutmodificatie | Zoutbehandeling verhoogt het aantal uitwisselbare kationen, verandert de oppervlaktelading, vergroot het aantal interne nanokanalen en verbetert de adsorptie. | Waterbehandeling, ionenadsorptie, bodemzuivering |

| Gecombineerde modificatie | Gecombineerd gebruik van zuur, base, zout, enz. om de adsorptieprestaties te verbeteren. | Waterbehandeling, dragermaterialen, bodemreiniging |

| Organische modificatie | Bij organische behandeling wordt een organische monolaag op het oppervlak gevormd, waardoor er dubbele organische-anorganische eigenschappen ontstaan, de hydrofiliteit/lipofiliteit verandert en het toepassingsbereik wordt uitgebreid. | Oppervlakteactieve stoffen, koppelingsmiddelen |

De belangrijkste modificatieprocessen omvatten momenteel thermische modificatie, anorganische modificatie (zuur-, alkali-, zoutmodificatie) en organische modificatie. Zuurmodificatie is hiervan het meest voorkomend. Veel onderzoekers passen zuurbehandeling toe op attapulgiet, terwijl onderzoek naar zoutmodificatie relatief beperkt is. Zoutmodificatie is milieuvriendelijker dan zuurmodificatie en zou in de toekomst verder onderzocht kunnen worden vanwege de lage CO2-voetafdruk. Organische modificatie heeft ook duidelijke voordelen ten opzichte van anorganische methoden, waarbij oppervlakteactieve stoffen en koppelingsmiddelen het meest worden gebruikt. De meeste studies richten zich nog steeds op enkelvoudige modificatiemethoden, die nu behoorlijk volwassen zijn. Daarom zou het overwegen van gecombineerde modificaties die de voordelen van meerdere methoden benutten, de effectiviteit van de modificatie kunnen verbeteren. De efficiëntie van opeenvolgende modificaties, zoals zuur- of warmtebehandeling, is sterk afhankelijk van de mate van attapulgietverpulvering.

3. Toepassingen en onderzoeksvoortgang van Attapulgiet

3.1 Geneesmiddeldrager

Vanwege het grote specifieke oppervlak en de sterke adsorptiecapaciteiten van attapulgiet wordt het veel gebruikt als drager voor hooggeconcentreerde pesticidepoeders. Als matrix voor granulaten. Met name voor vloeibare pesticiden kan de verwerking tot hooggeconcentreerde poeders of bevochtigbare poeders met attapulgiet als drager de vloeibaarheid en dispergeerbaarheid van de formulering beïnvloeden. De reologische en verdikkende eigenschappen van attapulgiet maken het veelgebruikt als verdikkingsmiddel in pesticidesuspensies.

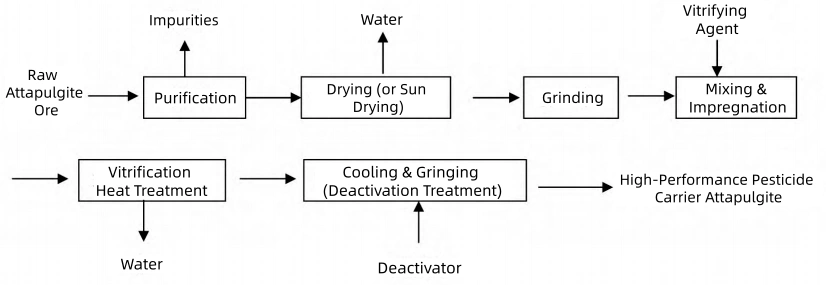

Voorbereidingsproces voor hoogwaardige pesticidedrager van Attapulgiet

Een tweestaps deactiveringsmethode levert hoogwaardige kleiproducten op. Na inerte modificatie neemt de oppervlaktezuurgraad van attapulgiet toe van pKa < 1,8 tot pKa > 3,3, met weinig verandering in het specifieke oppervlak. Het gemodificeerde attapulgiet kan worden gebruikt als drager voor pesticiden. Stabiliteitstests tonen aan dat de prestaties vergelijkbaar zijn met die van silicadragers. De sterke adsorptie-eigenschappen van attapulgiet blijven behouden, waardoor problemen zoals een beperkt toepassingsgebied en een korte houdbaarheid worden aangepakt.

Naast slimme pesticiden met langzame afgifte wordt attapulgiet ook gebruikt bij de productie van medicijnen voor menselijke consumptie. Het dient als adsorbens, suspendeermiddel en hulpstof in diverse geneesmiddelen. Er bestaan nationale normen voor attapulgiet en het wordt erkend als een veilig farmaceutisch materiaal.

3.2 Katalytische dragermaterialen

Dankzij zijn poreuze structuur versnelt attapulgiet de reactiesnelheid wanneer reactanten in de interne kanalen worden geadsorbeerd. Wanneer reactanten uit deze kanalen diffunderen, blijft het kristalrooster van attapulgiet intact, waardoor het een ideaal katalytisch dragermateriaal is. Hoogwaardige metalen, metaaloxiden en metaalzouten kunnen gelijkmatig op attapulgiet worden geladen, waardoor de volledige blootstelling van actieve centra en de overdracht van actieve stoffen worden vergemakkelijkt, wat de katalytische activiteit aanzienlijk verbetert. Momenteel wordt attapulgiet veel gebruikt voor katalytische stikstofbinding, afbraak van verontreinigende stoffen in water, verwijdering van luchtverontreinigende stoffen en zuurstofontwikkelingsreacties. Bij de bereiding van composietmaterialen zorgt gecontroleerde attapulgietverpulvering voor een uniforme dispersie in de polymeermatrix.

3.3 Energieopslagdragermaterialen

Attapulgiet is zelf niet-geleidend en kan niet direct worden gebruikt als elektrochemisch energieopslagmateriaal. Bestaande technologieën zoals templating en smeltdiffusiemethoden kunnen echter elektroactieve materialen in attapulgiet introduceren, waardoor het toepasbaar is op het gebied van elektrochemische energieopslag. Commerciële anodematerialen voor lithium-ionbatterijen bestaan voornamelijk uit koolstofhoudende materialen, die een lage specifieke capaciteit hebben. Attapulgiet kan worden gereduceerd door middel van aluminium-thermietreacties om van attapulgiet afgeleid silicium (SiATP) te produceren, dat koolstof als anodemateriaal in batterijen kan vervangen.

3.4 Colloïdale materialen

Wanneer attapulgiet wordt gedispergeerd in water of andere oplossingen met een lage concentratie, vormt het individuele staafkristallen of kleinere bundels, die zich vervolgens onder invloed van vanderwaalskrachten verstrengelen en een netwerkstructuur vormen, wat resulteert in een hoogviskeuze suspensie. Dit vertoont uitstekende colloïdale eigenschappen, waardoor attapulgiet een belangrijk onderdeel is van verdikkingsmiddelen, boorvloeistoffen en coatings.

3.5 Drankverhelderingsmiddelen en cosmetische additieven

Voedingsmiddelenindustrie: Attapulgiet werkt als een ontkleurings- en klaringsmiddel en bereikt een ontkleuringsgraad van 70% en een klaringsgraad van 90% voor eetbare oliën en dranken.

Cosmetische industrie: Deze sector is actief op het gebied van UV-bescherming, beheersing van talg en huidherstellende producten.

3.6 Milieu-adsorberende materialen

Momenteel verwijdert het actief zware metalen, organische kleurstoffen, antibiotica en andere verontreinigende stoffen uit afvalwater. Recente verkennende studies hebben ook de toepassing ervan onderzocht voor het adsorberen of verrijken van radioactieve stoffen in de nucleaire industrie. Dankzij de aanzienlijke vooruitgang in modificatieonderzoek breiden de soorten verontreinigende stoffen die attapulgiet kan adsorberen zich voortdurend uit. Attapulgietverpulvering verbetert de verwijderingsefficiëntie van verontreinigende stoffen door beter toegankelijke poriën en kanalen voor diffusie te creëren.

Belangrijkste adsorptiemechanismen voor verontreinigende stoffen

| Verontreinigende stof type | Metaalionen | Kleurstofmoleculen | Niet-metalen ionen | Radioactieve metaalionen |

| Belangrijkste adsorptiemechanismen | Elektrostatische interactie, chemische complexvorming, kationenuitwisseling, oppervlakteprecipitatie | Porie-adsorptie, elektrostatische interactie, waterstofbinding, chemische complexvorming | Porie-adsorptie, elektrostatische interactie | Elektrostatische interactie, chemische complexvorming |

3.7 Antimicrobiële materialen

Hoewel attapulgiet geen hoge antibacteriële activiteit heeft, kunnen de poriestructuur en oppervlakteactiviteit actieve antibacteriële stoffen opnemen en zo samengestelde antibacteriële materialen creëren. Enerzijds kan attapulgiet bacteriën fysiek adsorberen, wat de permeabiliteit van celmembranen beïnvloedt en de normale uitwisseling van materialen met de omgeving verhindert. Anderzijds vertonen de staafvormige kristallen van attapulgiet een naaldprikeffect. Het kan bacteriële celwanden en membranen beschadigen, waardoor bacteriën inactief worden.

Constructie van antibacteriële metaalcomposieten: Attapulgiet heeft regelmatige nanoschaalkanalen en functionele oppervlaktegroepen. Door de isomorfe substitutie tijdens de vorming draagt attapulgiet permanent negatieve ladingen en vormt het talrijke defecten of restbindingen in de structuur. Dit toont sterke adsorptiemogelijkheden voor pigmentmoleculen, zware metaalionen, kleurstoffen en antibiotica.

Attapulgiet met dodecyltrimethylammoniumbromide verlengt de antibacteriële werking met een lage biotoxiciteit.

De bismutvanadaat/attapulgiet-fotokatalysator breekt antibiotica 1,4 keer sneller af dan zuiver bismutvanadaat.

Naast de bovengenoemde antibacteriële materialen vertoont attapulgiet een goed toepassingspotentieel in composiet scaffoldmaterialen en wondgenezingsmaterialen. De daadwerkelijke toepassing van attapulgiet in de biomedische sector is echter nog relatief beperkt, waardoor de ontwikkeling van medische producten op basis van attapulgiet versneld moet worden. Snelle hemostatische gazen maken gebruik van de hoge adsorptiecapaciteit van attapulgiet en orthopedische of tandheelkundige substituten die de antibacteriële eigenschappen en biocompatibiliteit ervan optimaal benutten. In de diervoederindustrie is attapulgietverpulvering essentieel voor het bereiken van de fijne deeltjesgrootte die nodig is voor effectieve toxine-adsorptie en een uniforme menging.

3.8 Attapulgietvulmaterialen

De unieke vezelmorfologie van attapulgiet geeft het niet alleen de bijzondere eigenschappen van nanomaterialen, maar ook uitstekende vulcapaciteiten. Dit maakt het toepasbaar in polymeerversterking en papierproductie. In tegenstelling tot traditionele vulstoffen zoals calciumcarbonaat, kaolien en talk, die veel worden gebruikt in de papierproductie, vertoont vezelachtige attapulgiet een betere compatibiliteit met plantaardige vezels. In de kunststofverwerking zijn de vulprestaties van attapulgiet aanzienlijk beter dan die van andere anorganische vulstoffen. Het verbetert de mechanische, thermische en kristallisatie-eigenschappen van kunststoffen. Het optimaliseren van de parameters van attapulgietverpulvering, inclusief tijd en energie, is essentieel voor het in evenwicht brengen van productiekosten en prestatieverbetering.

3.9 Wrijvingsmaterialen

Fenolhars (PF), een typische thermohardende hars, wordt veel gebruikt in frictiematerialen vanwege de hoge hittebestendigheid, uitstekende mechanische eigenschappen en goede verwerkingsprestaties. De lage taaiheid en hoge wrijvingscoëfficiënt van pure PF beperken echter de toepassingen ervan in vaste smering. Moleculaire structuurmodificatie, doping van rubberdeeltjes en vezelversterking kunnen de tribologische eigenschappen van PF-composieten optimaliseren. Onderzoek wijst uit dat eendimensionale attapulgiet (AT) nanovezels een significant synergetisch versterkend effect vertonen wanneer ze worden gebruikt in combinatie met microvezels met hoge modulus (CF, GF) in PF-composieten. Wanneer attapulgiet 20% van de massafractie uitmaakt, bedraagt de druksterkte van de multi-nano composietmaterialen GF/AT/PF en CF/AT/PF meer dan 400 MPa. Dit duidt op een extreem hoog draagvermogen.

3.10 Dierlijke productiematerialen en voederadditieven

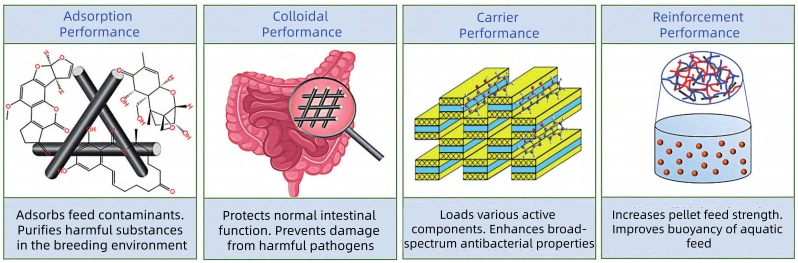

In de veehouderij kan attapulgiet dienen als adsorbens voor het absorberen van zware metalen, mycotoxinen, bacteriën en bacteriële toxines, waardoor de integriteit van de darmwand van het dier behouden blijft. Bovendien kunnen zowel anorganische als organische modificaties de biologische activiteit ervan verbeteren, waarbij gemodificeerd attapulgiet goede antibacteriële eigenschappen vertoont. Studies hebben aangetoond dat het toevoegen van attapulgiet aan voer de immuniteit en antioxiderende werking van het darmslijmvlies kan verbeteren. Het kan ook de microbiële balans in de darm reguleren, de morfologie van het darmslijmvlies verbeteren, de groei en ontwikkeling van dieren bevorderen en de productieprestaties verbeteren. Attapulgiet kan ook effectief door pathogenen veroorzaakte schade aan de darmwand van het dier beperken.

Gezien de vele voordelen kan attapulgiet dienen als pelletbinder, als drager voor sporenelementen en als adsorbens voor zware metalen in veevoer.

Functionele prestaties van attapulgiet in diervoeder

3.11 Additieven voor lithiumbatterijmaterialen

De afgelopen jaren hebben onderzoekers uitgebreid onderzoek gedaan naar kleimineralen, vertegenwoordigd door attapulgiet, in de batterijsector. Ze ontdekten dat attapulgiet de groei van lithiumdendriet remt, wat een nieuwe benadering biedt voor de bescherming van anodes van lithiummetaalbatterijen.

Onderzoek heeft aangetoond dat het laden van attapulgiet op vezelmembranen effectief kan zijn voor de bescherming van de anode van lithiummetaalbatterijen. Symmetrische batterijen en volle lithium-ijzerfosfaatbatterijen werden geassembleerd voor elektrochemische tests. Onderzoek wijst uit dat vezelmembranen met attapulgiet de groei van lithiumdendriet effectief onderdrukken. De polarisatiespanning bedroeg slechts 83,2 mV na 500 uur cycli bij een depositiecapaciteit van 1 mA·h/cm² en een stroomdichtheid van 2 mA/cm². De volle batterij met toegevoegde attapulgietvezelmembranen behield een ontladingscapaciteit van 84,92 mA·h/g na 1000 cycli met een ontladingssnelheid van 1C.

Conclusie

De unieke staafstructuur en kanaalarchitectuur van attapulgiet hebben de afgelopen jaren de aandacht getrokken voor de precieze en doelgerichte constructie van nieuwe nanofunctionele materialen. Deze producten zullen naar verwachting voldoen aan de toepassingseisen voor adsorptie, katalyse en composietmaterialen. Naarmate fundamenteel en toegepast onderzoek zich verder verdiept, zal het toepassingsproces van attapulgiet in nanofunctionele toepassingen vorderen. Dit bevordert de hoogwaardige ontwikkeling van minerale functionele materialen en verhoogt continu de toegevoegde waarde van producten. Deze vooruitgang zal de modernisering van de attapulgietindustrie stimuleren en bijdragen aan een duurzame industriële ontwikkeling.

Over Epic Powder

Epische poedermachines is gespecialiseerd in straalverpulveringstechnologie. Onze straalmolen MQW40 zorgt voor een efficiënte verwerking van materialen en verbetert hun eigenschappen voor diverse toepassingen. Met onze expertise in poederverpulvering en onze toewijding aan kwaliteit ondersteunen wij industrieën bij het bereiken van hun doelen met superieure materialen. Neem vandaag nog contact met ons op voor een oplossing op maat.