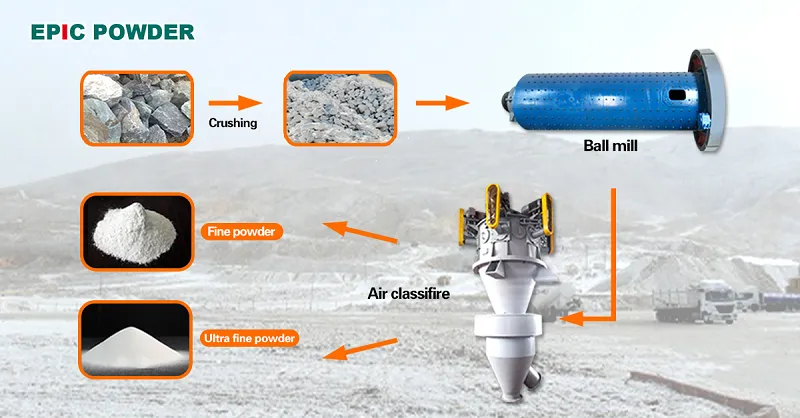

In de wereld van poedermaterialen neemt siliciumdioxide (SiO₂) een centrale positie in. Het kent diverse vormen en een breed scala aan toepassingen. De verschillende productvormen – zoals kwartspoeder, silicadamp, microsilica en wit roet – worden echter vaak door elkaar gehaald. Hoewel deze materialen een gemeenschappelijke oorsprong hebben, verschillen ze aanzienlijk in fysische eigenschappen, productieprocessen en toepassingsgebieden. Een duidelijk onderscheid tussen deze materialen is cruciaal voor materiaalselectie, procesoptimalisatie en productinnovatie. Dit artikel biedt een heldere analyse van de verschillen en verbanden tussen deze vier veelvoorkomende siliciumpoeders. Het helpt u hun materiaaleigenschappen nauwkeurig te begrijpen en uw productonderzoek, -ontwikkeling en -productie te optimaliseren. Epic Powder is gespecialiseerd in het ultrafijn malen van kwarts, nauwkeurige classificatie en oppervlaktebehandeling. Onze zelfontwikkelde maalinstallaties en luchtclassificatoren worden veelvuldig gebruikt bij de productie van hoogwaardige poeders.

De verschillen tussen de vier siliciumpoeders

Zowel kwartspoeder als silicaroet verwijzen naar kristallijne SiO₂-poeders, die in principe worden verkregen door gesteente tot fijne deeltjes te vermalen. Kwartspoeder is relatief grof, terwijl silicaroet fijner is. Door ruw kwartserts te vermalen met behulp van diverse verwerkingsmachines, kan men kwartspoeder verkrijgen. Silicaroet daarentegen is een ultrafijn poeder dat wordt geproduceerd door kwartserts tot een bepaalde zuiverheid te vermalen of door middel van chemische methoden om fijne silicadeeltjes te verkrijgen. Ze verschillen echter in fysische eigenschappen, chemische samenstelling en toepassingsgebieden.

Microsilica, ook wel silicadamp genoemd, is een industrieel bijproduct dat wordt opgevangen uit de rook en het stof van smeltovens. Het bevat fijn stof met een hoog silicagehalte. In de uitgestoten rook vertegenwoordigt SiO₂ ongeveer 901 TP3T van het totale stof, met extreem kleine deeltjesgroottes, vaak op nanoniveau, vandaar de naam "silicadamp".

Wit roet is een ultrafijn silicapoeder dat wordt geproduceerd via chemische methoden, zoals dampfase- of precipitatiemethoden. Het komt voor als een wit poeder, korrels of onregelmatige brokken. Dampfase-wit roet bestaat volledig uit nanosiliciumdioxide, met een zuiverheid tot 99% en een deeltjesgrootte van 10-20 nm, maar het productieproces is complex en kostbaar. Precipitatie-wit roet omvat traditionele en speciale precipitatiemethoden. De traditionele methode gebruikt zwavelzuur, zoutzuur, CO₂ en natriumsilicaat als grondstoffen. De speciale methode maakt gebruik van technieken zoals ultra-zwaartekrachttechnologie, sol-gelmethoden, chemische kristallisatie, secundaire kristallisatie of omgekeerde micel-micro-emulsie. Wit roet is een poreus materiaal met de samenstelling SiO₂·nH₂O, waarbij nH₂O aanwezig is in de vorm van oppervlaktehydroxylgroepen. Het is hittebestendig, niet-ontvlambaar, geurloos en heeft uitstekende elektrische isolatie-eigenschappen.

Silicadamp

Silicadamp is zeer fijn, niet-kristallijn siliciumdioxide dat in elektrische vlamboogovens wordt geproduceerd als bijproduct van de productie van elementair silicium of legeringen die silicium bevatten. Dit gerecyclede materiaal kan rechtstreeks aan beton worden toegevoegd als afzonderlijk ingrediënt of in een mengsel met portlandcement en silicadamp.

Silicapoeder bestaat voornamelijk uit amorf (niet-kristallijn) siliciumdioxide (SiO2). De afzonderlijke deeltjes zijn extreem klein, ongeveer 1/100e van de grootte van een gemiddeld cementdeeltje. Door de fijne deeltjes, het grote oppervlak en het hoge SiO2-gehalte is silicapoeder een zeer reactieve puzzolaan wanneer het in beton wordt gebruikt.

Voordelen van silicaroet

- Silica-fumebeton met een laag watergehalte is zeer bestand tegen indringing van chloride-ionen, waardoor corrosie veroorzaakt door dooimiddelen of zeezouten wordt voorkomen.

- Het is verkrijgbaar in natte of droge vorm.

- De kleine deeltjesgrootte, die 100 keer fijner is dan die van gewone portlandcementcompounds, zorgt voor een kogellagereffect dat het thixotrope gedrag verbetert en daarmee de viscositeit van het beton beïnvloedt.

- Het grote oppervlak van silicadampdeeltjes beïnvloedt de mobiliteit van water in beton, waardoor ontmenging en waterafscheiding in het beton vrijwel volledig worden voorkomen.

- Hoge cohesieve verwerkbaarheid en het vermogen om beton over lange afstanden te verpompen.

- Wordt gebruikt om de mechanische eigenschappen en duurzaamheid van beton te verbeteren.

Verschillen tussen silicadamp en kwartspoeder

Fysische eigenschappen

Zowel silicadamp als kwartspoeder zijn fijne materialen met deeltjesgroottes die doorgaans kleiner zijn dan 1 micron. Hun fysische eigenschappen verschillen echter. Silicadamp is meestal licht, los en heeft een lage dichtheid, terwijl kwartspoeder dichter en zwaarder is.

Chemische samenstelling

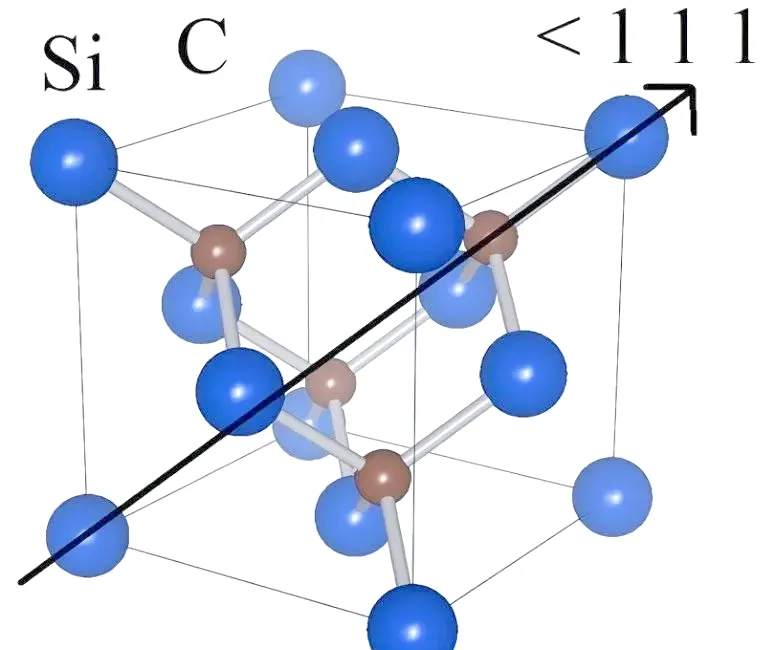

Ook chemisch gezien verschillen silicadamp en kwartspoeder van elkaar. Silicadamp is een vorm van siliciumdioxide (SiO₂) met een kristalstructuur die lijkt op die van kwarts, maar vaak amorf is vanwege de kleine deeltjesgrootte en veel actieve oppervlaktegroepen bevat. Kwartspoeder daarentegen wordt geproduceerd door het vermalen van grote kwartskristallen en heeft eveneens de chemische samenstelling SiO₂.

Toepassingsgebieden

Beide materialen worden veelvuldig in de industrie gebruikt, maar in verschillende toepassingsgebieden. Silicapoeder wordt veel gebruikt in de elektronica, optica, keramiek, cosmetica, coatings en kunststoffen om de materiaalstabiliteit te verhogen, de kosten te verlagen en de verwerkingsprestaties te verbeteren. Kwartspoeder wordt voornamelijk gebruikt in glas, keramiek, cement, bouwmaterialen en metaalcoatings, waar de hoge hardheid en chemische stabiliteit het een belangrijk bestanddeel maken in veel functionele materialen.

Over Epic Powder

Episch poeder Wij zijn gespecialiseerd in onderzoek, ontwikkeling en productie van geavanceerde poederverwerkingstechnologieën. We bieden innovatieve oplossingen voor industrieën die gebruikmaken van niet-metallische mineralen zoals kwarts, silica, calciumcarbonaat en meer. Episch poeder Epic Powder is gespecialiseerd in ultrafijn malen, nauwkeurige classificatie en oplossingen voor oppervlaktebehandeling. Onze zelfontwikkelde maalinstallaties en luchtclassificatoren worden veelvuldig gebruikt bij de productie van hoogwaardige poeders zoals kwarts. Met een focus op kwaliteit en duurzaamheid biedt Epic Powder haar klanten geavanceerde poederoplossingen die zijn afgestemd op hun specifieke behoeften.

Bedankt voor het lezen. Ik hoop dat mijn artikel je helpt. Laat hieronder een reactie achter. Je kunt ook contact opnemen met de online klantenservice van EPIC Powder. Zelda voor verdere vragen.”

— Jason Wang, Senior ingenieur