Santrifüj Sınıflandırıcı Nedir?

Santrifüjlü hava ayırıcı veya toz sınıflandırıcı olarak da bilinen santrifüjlü sınıflandırıcı, toz parçacıklarını boyutlarına göre ayırır. Bu işlemi gerçekleştirmek için santrifüj kuvveti ve hava akışı kullanır: Makine, toz beslemesini dönen bir hazne içinde yüksek hızlarda döndürür. Bu işlem, daha iri parçacıkları dışarı iten güçlü bir santrifüj kuvveti oluştururken, hava akışı da askıda kalan daha ince parçacıkları uzaklaştırır.

Nasıl Çalışır?

Toz besleme girişi: Malzeme sınıflandırıcıya girer ve dönen rotor tarafından yakalanır.

Merkezkaç kuvveti: Rotorun hızlı dönüşü daha büyük ve ağır parçacıkları dış duvara doğru iter.

Hava akışı ayrımı: Kontrollü bir hava akışı, daha ince parçacıkları sınıflandırıcının çıkışına doğru kaldırır.

Parçacık boyutu sınıflandırması: Sınıflandırıcı, rotor hızını ve hava akışını ayarlayarak genellikle 32 ila 250 mikrometre arasında değişen tozları ayırır.

Bu işlem kuru tozları etkili bir şekilde sınıflandırır ve derecelendirir, bu da santrifüjlü sınıflandırıcıları kuvars tozu derecelendirmesi veya mineral ince maddelerinin ayrılması gibi hassas parçacık boyutu kontrolü gerektiren uygulamalar için ideal hale getirir.

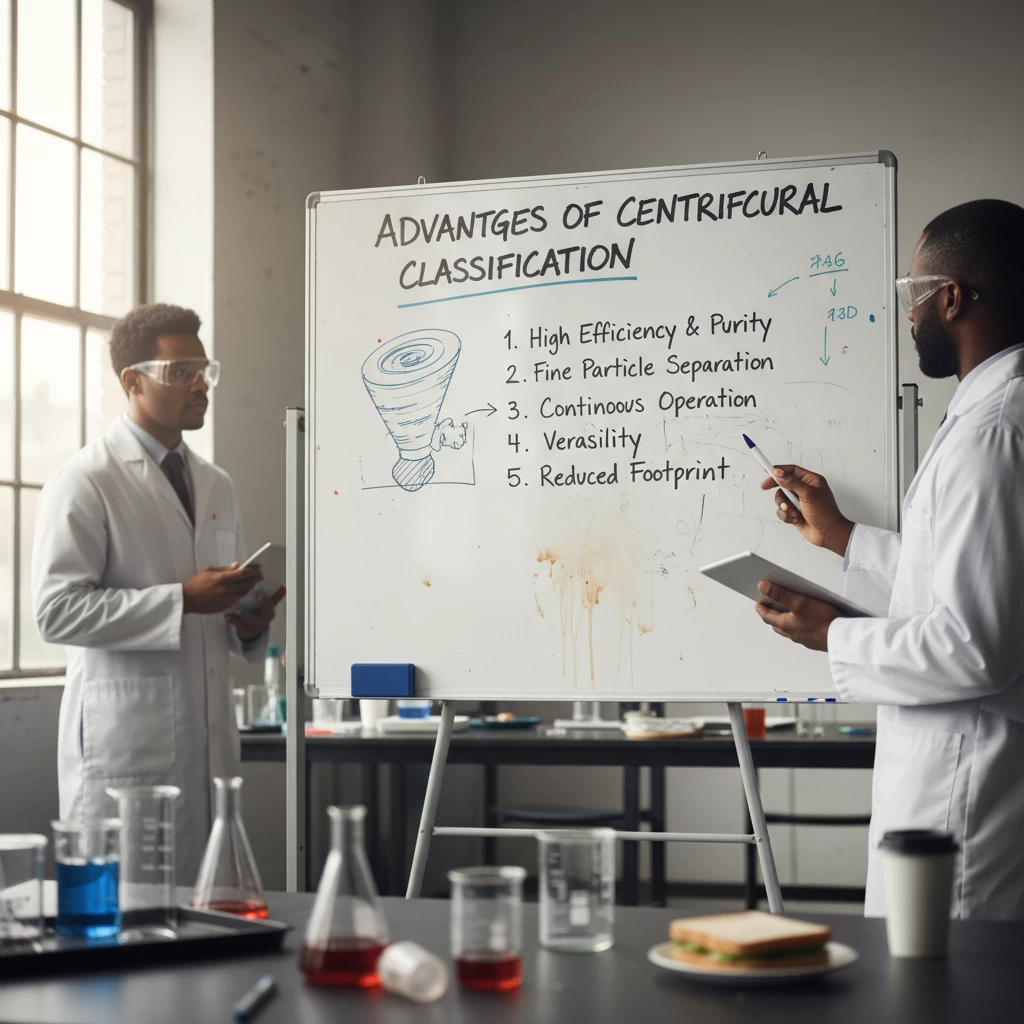

Neden Santrifüj Sınıflandırmayı Seçmelisiniz?

Santrifüjlü sınıflandırma, geleneksel eleklere ve hidrosiklonlara kıyasla birkaç temel nedenden dolayı öne çıkmaktadır. Daha keskin parçacık boyutu ayrımı, gelişmiş verimlilik ve daha az bakım zahmeti sunar. Özellikle mineral işleme ve kuvars tozu sınıflandırması gibi ABD endüstrilerinde toz ayrımı için neden mantıklı olduğunu aşağıda açıklıyoruz:

| Avantaj | Santrifüjlü Sınıflandırıcı | Geleneksel Ekranlar | Hidrosiklonlar |

| Ayırma Doğruluğu | Yüksek hassasiyet, daha sıkı kesim noktaları | Daha düşük doğruluk, genellikle daha az tutarlılık | Orta düzeyde doğruluk |

| Aşınma ve Yıpranma | Daha az aşınma; aşınmaya dayanıklı astarlar | Yırtılma ve körleşmeye eğilimli ekranlar | Astarlarda aşınma şiddetli olabilir |

| Parçacık Boyut Aralığı | 32-250μm arası tozları kolayca işler | Daha ince tozlarla mücadele eder | Daha iri parçacıklar için iyi |

| Enerji Verimliliği | Ayarlanabilir hava akışıyla daha az güç kullanır | Daha fazla güç ve sık temizlik gerektirir | Orta düzeyde güç tüketimi |

| Bakım | Basit cıvatalı parçalar, bakımı kolay | Sık ekran değişimleri | Rutin astar değişimine ihtiyaç var |

| Kuru Toz Taşıma | Kuru uygulamalar ve atalet sınıflandırması için mükemmeldir | Ekranlar kuru tozlarla tıkanabilir | Çoğunlukla ıslak veya bulamaç yemler |

Kısacası, santrifüjlü sınıflandırmayı seçmek, daha az kesintiyle parçacık boyutları üzerinde daha iyi kontrol anlamına gelir. Geleneksel yöntemlerin sıkıntıları olmadan güvenilir, düşük bakım gerektiren toz ayırma istiyorsanız, bu akıllıca bir seçimdir. Bu, üretim kalitesini artırırken işletme maliyetlerini düşürmek isteyen Amerikalı üreticiler için idealdir.

DESTANSI CTC Serisi Özellikleri ve Avantajları

EPIC CTC Serisi santrifüjlü sınıflandırıcılar, akıllı tasarımları ve güvenilir performanslarıyla öne çıkıyor. İşte onları toz sınıflandırması için sağlam bir tercih yapan özellikler:

Aşınmaya dayanıklı astarlar: Aşınma ve yıpranmayı azaltan dayanıklı malzemelerle üretilmiştir, aşındırıcı minerallerle bile daha uzun makine ömrü sağlar.

Ayarlanabilir hava akışı: Kesim noktalarını kontrol etmek için hava akışını kolayca ayarlayın, 32-250μm arasında hassas parçacık boyutu sınıflandırması elde edin.

Enerji verimliliği: Çıkış kalitesinden ödün vermeden enerji maliyetlerinizi düşürerek hava akışını ve motor gücünü optimize etmek için tasarlanmıştır.

Kompakt ve modüler tasarım: Değerli zemin alanından tasarruf sağlar ve kurulum veya bakımı kolaylaştırır.

Tutarlı kalitede çıktı: Ataletsel hava sınıflandırıcı düzeneği sayesinde her seferinde homojen parçacık ayrımı elde edersiniz.

| Özellik | Fayda |

| Aşınmaya dayanıklı astarlar | Daha uzun ekipman ömrü |

| Ayarlanabilir hava akışı | Hassas parçacık boyutu kontrolü |

| Enerji tasarruflu sistem | Azaltılmış güç tüketimi |

| Modüler tasarım | Kolay kurulum ve bakım |

| Kararlı sınıflandırma | Yüksek kaliteli toz sınıflandırması |

CTC Serisi hakkında detaylı özellikler ve daha fazlası için resmi Santrifüjlü Sınıflandırıcı sayfasıBu model özellikle kuvars tozu sınıflandırması ve diğer ince mineral işleme ihtiyaçları için uygundur.

EPIC CTC Serisi Santrifüj Sınıflandırıcıların Teknik Özellikleri

EPIC CTC Serisini özellikle ABD pazarı için toz sınıflandırmasında etkili kılan temel özelliklere hızlı bir bakış:

| Şartname | Detaylar |

| Parçacık boyut aralığı | 32 – 250 μm |

| Kapasite | 500 ila 3000 lbs/saat (modele bağlı) |

| Güç gereksinimi | 5 ila 20 HP (boyuta göre değişken) |

| Malzemeler | Paslanmaz çelik ve aşınmaya dayanıklı astarlar |

| Mevcut modeller | CTC-500, CTC-1000, CTC-2000, CTC-3000 |

Parçacık boyut aralığı: Kuvars tozu sınıflandırıcı ve mineral ince tane ayırıcı uygulamaları gibi ince tozlar için mükemmeldir.

Kapasite: Küçük laboratuvarlardan büyük üretim alanlarına kadar geniş bir hacim yelpazesini idare eder.

Güç: İşletme maliyetlerinizi optimize etmek için tasarlanmış enerji tasarruflu motorlar.

Yapım malzemeleri: Çalışma süresini azaltmak ve ömrünü uzatmak için aşınmaya dayanıklı astarlara sahip ağır hizmet tipi paslanmaz çelik çerçeveler.

Model seçenekleri: Üretim ölçeğinize göre bir model seçin; ister düşük hacimli ister yüksek çıktılı olsun.

Bu kombinasyon, ABD'deki endüstrilerdeki kuru toz ayırıcı ihtiyaçları için ideal olan esneklik ve dayanıklılık ile tutarlı parçacık boyutu sınıflandırması elde etmenizi sağlar.

Uygulamalar ve Vaka Çalışmaları

EPIC CTC Serisi Santrifüj Sınıflandırıcı, ABD'deki endüstrilerin çeşitli toz sınıflandırma ihtiyaçları için sağlam bir seçimdir. İşte öne çıktığı noktalar:

Kuvars Tozu Sınıflandırması: 32-250μm arasındaki kuvars tozlarını ayırmak için mükemmeldir, cam yapımı veya elektronik gibi kullanımlar için ince, tutarlı parçacık boyutu sağlar.

Uçucu Kül Sınıflandırması: Enerji santrallerinin ve çimento üreticilerinin hassas uçucu kül parçacık boyutlarına ulaşmalarına yardımcı olur, betonun dayanıklılığını artırır ve atıkları azaltır.

Maden İşleme: Madencilik faaliyetlerinde mineral ince taneciklerinin ayrıştırılması, cevher kalitesinin ve geri kazanım oranlarının artırılması için idealdir.

Bu sınıflandırıcılar, güvenilir ve tutarlı bir sınıflandırma sağlar ve doğruluk ve dayanıklılığın en önemli olduğu ağır hizmet tipi kullanımlarda kendini kanıtlamıştır. Kuru tozlarla çalışıyorsanız ve hassas parçacık boyutu sınıflandırmasına ihtiyacınız varsa, EPIC'in santrifüjlü hava ayırıcısı tam size göre.

Santrifüj Sınıflandırıcı için Kurulum ve Bakım Kılavuzları

EPIC CTC serisi santrifüj sınıflandırıcının kurulumu kolaydır. Ünite, özel aletler veya ekstra parçalar olmadan hızlı bir şekilde sabitlenebilmesi için basit bir cıvatalama kurulumuna sahiptir. Bu, ABD'deki yoğun tesislerde kesinti süresinin en aza indirilmesi gerektiği durumlar için idealdir.

Kurulum İpuçları

Sağlam temel: Zeminin veya platformun düz olduğundan ve makinenin ağırlığını destekleyecek kadar sağlam olduğundan emin olun.

Uygun hava akışı bağlantıları: Hava geçirmez contaların olduğundan emin olmak için tüm kanalları kontrol edin; bu, sınıflandırmanın etkili olmasını sağlar.

Güç kaynağı: Güç sorunlarını önlemek için elektrik tesisatının ünitenin özelliklerine uygun olduğundan emin olun.

Bakımı Kolaylaştırıldı

Santrifüjlü hava ayırıcınızı en iyi durumda tutmak için sadece biraz düzenli bakıma ihtiyacınız var:

Rutin muayene: Aşınmaya dayanıklı astarlarda hasar veya incelme belirtileri olup olmadığını kontrol edin.

Düzenli olarak temizleyin: Performansı korumak için özellikle hava akış sisteminin etrafındaki toz birikimini temizleyin.

Hareketli parçaları yağlayın: Herhangi bir mekanik aşınmayı önlemek için kullanım kılavuzundaki çizelgeyi takip edin.

Performansı izleyin: Kesme noktasının doğruluğundaki değişimlere dikkat edin; bu, ayarlama veya onarım ihtiyacının sinyali olabilir.

Sorun Giderme Hızlı Düzeltmeleri

Sorunlar ortaya çıktığında, bu adımlar genellikle yaygın sorunları çözer:

Tutarlı olmayan parçacık boyutlandırması: Hava akışı ayarlarını doğrulayın ve tıkanıklık olup olmadığını kontrol edin.

Alışılmadık sesler: Yatakları ve motor bağlantılarını gevşeklik veya aşınma açısından inceleyin.

Azaltılmış kapasite: Filtreleri ve ayırıcı bölmeleri tıkalı maddelerden temizleyin.

Sadece biraz planlı bakım, santrifüjlü sınıflandırıcınızın güvenilir bir şekilde çalışmasını ve toz sınıflandırmasının yıllarca hassas kalmasını sağlar.

Neden EPIC Toz Makinaları?

Seçmek EPIC Toz Makinaları Bu, birinci sınıf Alman mühendisliğinin güvenilir ABD merkezli destekle birleştiği anlamına gelir. EPIC CTC serisi de dahil olmak üzere santrifüjlü sınıflandırıcılarımız, özellikle kuvars tozu sınıflandırma ve mineral işleme alanlarında toz sınıflandırma görevlerinde hassasiyet ve dayanıklılık sağlamak üzere tasarlanmıştır.

EPIC'in öne çıkmasının nedenleri:

Hassasiyet ve Performans: Alman tasarımı, kararlı ve doğru parçacık boyutu sınıflandırmasını garanti eder.

Yerel Destek: Operasyonlarınızın sorunsuz bir şekilde yürütülmesini sağlamak için ABD'de hızlı ve duyarlı müşteri hizmetleri sunuyoruz.

Kanıtlanmış Güvenilirlik: Ülke genelindeki müşteriler, tutarlı sonuçlar ve enerji verimliliği için EPIC'e güveniyor.

Gerçek Geri Bildirim: Müşterilerimizin referansları kolay kurulum, minimum kesinti süresi ve mükemmel ürün kalitesini vurgulamaktadır.

EPIC Powder Machinery, sınıflandırma sürecinizi kolaylaştırırken üretkenliğinizi artırmaya odaklanır. Santrifüjlü hava ayırıcı teknolojimiz hakkında daha fazla bilgi için şu sayfamıza göz atın: CTC serisi sınıflandırıcı sayfası.

Sıkça Sorulan Sorular (SSS)

Santrifüj Sınıflandırıcıda kesme noktası ne kadar doğrudur?

Kesim noktası oldukça hassastır ve genellikle 32-250 μm arasındaki tozları ayırır. Tutarlı parçacık boyutu sınıflandırması bekleyebilirsiniz; bu da onu ince kuvars tozu sınıflandırması ve mineral ince taneciklerinin ayrılması için güvenilir kılar.

EPIC CTC Serisi ıslak beslemeleri idare edebilir mi?

Bu sınıflandırıcılar esas olarak kuru toz ayırma için tasarlanmıştır. Islak beslemeler önerilmez çünkü nem, hava akışını ve sınıflandırma verimliliğini etkileyebilir. Islak malzemeler için hidrosiklonlar gibi diğer ekipmanlar daha uygun olabilir.

Hangi toz türlerini sınıflandırabilir?

Santrifüjlü hava ayırıcı, kuvars tozları, uçucu kül, mineral ince parçacıklar ve sıkı parçacık boyutu kontrolü gerektiren benzeri kuru malzemeler gibi çeşitli tozlarla iyi çalışır.

Hava akışı ve sınıflandırma ayarlarını yapmak kolay mı?

Evet, CTC Serisi ayarlanabilir hava akışı kontrollerine sahiptir ve bu sayede ürününüzün özel ihtiyaçlarına uyacak şekilde ayrımı hassas bir şekilde ayarlayabilirsiniz.

Bakım ne sıklıkla yapılmalıdır?

Her şeyin sorunsuz çalışması için genellikle birkaç haftada bir yapılan rutin kontroller ve temizlik yeterlidir. Aşınmaya dayanıklı astarlar, arıza sürelerini azaltmaya yardımcı olur.

Geleneksel eleklerin veya hidrosiklonların yerini tamamen alabilir mi?

Kuru toz sınıflandırması için evet. Daha iyi verimlilik ve enerji tasarrufu sağlar, ancak ıslak veya yapışkan malzemeler için yine de tamamlayıcı ekipmanlara ihtiyacınız olabilir.

Sınıflandırıcı enerji tasarruflu mu?

Kesinlikle. Tasarım, eski teknolojilere kıyasla güç kullanımını en aza indirerek uzun vadede tasarruf sağlıyor.

Başka teknik sorularınız varsa veya uygulamanıza özel tavsiye almak istiyorsanız, bize ulaşmaktan çekinmeyin; size yardımcı olmak için buradayız.

Satın Almaya Hazır mısınız? Hemen Destek Alın

İhtiyaçlarınıza uygun bir santrifüj sınıflandırıcı mı arıyorsunuz? Kolay satın alma ve sağlam destek hizmetlerimizle size yardımcı olmak için buradayız.

Nasıl Başlanır

| Adım | Ne Elde Edersiniz | Nasıl Yardımcı Oluyoruz |

| Teklif İsteyin | Projeniz için doğru fiyatlandırma | Ekibimizden hızlı yanıtlar |

| Bir Demo Planlayın | EPIC CTC Serisini aksiyonda görün | Canlı veya sanal demolar mevcuttur |

| İlgili Ürünleri Keşfedin | Tamamlayıcı ekipman bulun | Kurulumunuz için özel çözümler |

Destek İçin Neden Bizi Seçmelisiniz?

Uzman tavsiyesi ABD endüstrilerine özel olarak tasarlandı

Güvenilir müşteri hizmetleri sorun gidermeye hazır

Parçalara ve bakım yardımına erişim ülke çapında

Projenizi görüşmek ister misiniz? Hemen bizimle iletişime geçin ve kuvars tozu sınıflandırması, mineral ince taneciklerinin ayrılması ve daha fazlası için tasarlanmış en iyi santrifüjlü hava ayırıcısını edinin.

Santrifüjlü sınıflandırıcı modellerimizi keşfedin doğru uyumu bulmak için bir demo planlayın Bugün!