Yüksek saflıkta kuvars hammaddeleri, yüksek kaliteli kuvars ürünleri üretmek için hayati önem taşır ve sonraki arıtma işlemlerinin etkinliği büyük ölçüde ilk hammadde kalitesine bağlıdır. Yüksek saflıkta kuvars elde etmek, istenen parçacık boyutlarına ulaşmak için belirli aşamalarda hassas kuvars taşı öğütme de dahil olmak üzere gelişmiş madencilik teknolojileri ve işleme tekniklerine dayanır. İşte yüksek saflıkta kuvars hammaddeleri elde etme yöntemlerine dair ayrıntılı bir giriş:

1. Madencilik Teknolojisi: Yönlü delme ve yerinde kırma gibi modern teknikler, yüksek saflıkta kuvars cevherinin hassas bir şekilde çıkarılmasını sağlar. Bu yöntemler, cevherin dış ortama maruz kalmasını en aza indirerek kontaminasyonu azaltır. Ayrıca, kırma ve taşıma sırasındaki sıkı kontroller, cevherin saflığının korunmasını sağlar.

2. İşleme ve Arıtma Teknolojisi: Çıkarılan cevher, yüksek saflıkta kuvars hammaddesi elde etmek için bir dizi işleme ve saflaştırma aşamasından geçer. Bu aşamalar, kırma, eleme, manyetik ayırma ve safsızlıkları gidermek için flotasyon işlemlerini içerir. Kimyasal saflaştırma ve yüksek sıcaklıkta füzyon gibi gelişmiş saflaştırma teknikleri, hammaddenin saflığını daha da artırır.

Tablo: Yüksek Saflıkta Kuvars Hammaddelerinin Elde Edilmesinde Temel Adımlar ve Rolleri

| Adım | Ana İçerik | Rol |

| Madencilik | Yönlü sondaj kullanımı & yerinde kırma | Cevher saflığını ve kalitesini garanti eder |

| İşleme ve Arıtma | Kırma, eleme, manyetik ayırma, flotasyon (fiziksel yöntemler) | Kirlilikleri ve istenmeyen bileşenleri temizler |

| Kimyasal Arıtma | Belirli safsızlıkları gidermek için kimyasal reaksiyonların kullanılması | Hammadde saflığını artırır |

| Yüksek Sıcaklık Füzyon | Yüksek sıcaklıkta eritme işlemi yoluyla kalan safsızlıkların giderilmesi | Yüksek saflıkta kuvars hammaddesi elde edilir |

Yukarıda belirtilen yöntem ve adımlar sayesinde, yüksek saflıkta kuvars hammaddeleri elde edilebilir ve bu da sonraki kuvars malzeme arıtma süreçleri ve yeni malzeme araştırma ve geliştirme çalışmaları için sağlam bir temel oluşturur. Teknolojik gelişmelerle birlikte, yüksek saflıkta kuvars hammaddelerine olan talep artmaya devam etmekte ve bu da daha verimli edinim yöntemlerinin araştırma ve geliştirilmesini özellikle önemli hale getirmektedir.

1 Kuvars Cevherinin Madenciliği ve Ön İşlemleri

Kuvars malzeme üretim sürecinde, kuvars cevherinin çıkarılması ve ön işleme tabi tutulması hayati bir aşamadır. İlk olarak, kuvars cevheri yatağının büyüklüğüne ve coğrafi konumuna bağlı olarak, açık ocak veya yeraltı madenciliği gibi uygun bir madencilik yöntemi seçilir. Açık ocak madenciliği büyük ve düz yataklar için uygunken, yeraltı madenciliği karmaşık jeolojik koşullara sahip zengin yataklar için uygundur.

Çıkarılan kuvars cevheri, safsızlıkları gidermek ve diğer minerallerin içeriğini azaltmak için ön işlem gerektirir. Ön işlem, temel olarak kırma, eleme, manyetik ayırma ve flotasyon gibi adımları içerir. Kırma, büyük cevher parçalarını daha sonraki işlemleri kolaylaştırmak için daha küçük parçalara ayırır. Eleme, titreşimli elekler kullanılarak farklı boyutlardaki kuvars cevheri parçacıklarını ayırır. Manyetik ayırma, kuvars cevheri ile safsızlıklar arasındaki manyetik farklardan yararlanarak bunları ayırır. Flotasyon ise yoğunluk farklarını kullanır ve kuvars cevherindeki safsızlıkları ayırmak için kabarcıklar kullanır.

Ön işlem sırasında kuvars cevherinin kimyasal olarak saflaştırılması da gereklidir. Yaygın kimyasal saflaştırma yöntemleri arasında asit liçi, alkali liçi ve oksidasyon kavurma bulunur. Asit liçi, kuvars cevherindeki safsızlıklarla reaksiyona girerek onları uzaklaştırmak için hidroflorik veya sülfürik asit gibi asidik çözeltiler kullanır. Alkali liçi ise safsızlıklarla reaksiyona girerek saflaştırma sağlamak için sodyum hidroksit veya sodyum karbonat gibi alkali çözeltiler kullanır. Oksidasyon kavurma, kuvars cevherindeki safsızlıkları oksitlere veya diğer bileşiklere dönüştürmek için yüksek sıcaklıkta kalsinasyon içerir ve böylece kuvars cevherinin saflığını artırır.

Ayrıca, ön işleme sırasında nem kontrolü de önemlidir. Kuvars cevherinin genellikle yüksek nem içeriği nedeniyle, etkisiz bir kontrol, sonraki arıtma işlemlerinin ve yeni malzeme geliştirmenin kalitesini etkileyebilir. Bu nedenle, nem içeriğini azaltmak için ön işleme sırasında kurutma işlemi uygulanır.

Kuvars cevherinin madenciliği ve ön işlemesi, kuvars malzeme saflaştırma sürecinin ve yeni malzeme Ar-Ge'sinin önemli halkalarıdır. Kuvars cevherinin madencilik, kırma, eleme, manyetik ayırma, flotasyon, kimyasal saflaştırma ve nem kontrolü yoluyla işlenmesiyle, kuvars malzeme üretimi için yüksek kaliteli hammaddeler elde edilebilir ve böylece tüm üretim sürecinin verimliliği ve nihai ürün kalitesi artırılabilir.

Doğal Kuvars için 2 Kırma ve Sınıflandırma Teknolojisi

Doğal kuvarsın ezilmesi ve sınıflandırılması, yüksek saflıkta kuvars malzemelerinin hazırlanmasında temel adımlardır. Amaç, büyük kuvars hammaddelerini mekanik kuvvet kullanarak sonraki saflaştırma işlemlerinin gerekliliklerini karşılayan parçacıklara ayırmak ve sonraki kimyasal saflaştırmanın verimliliğini ve nihai ürün saflığını artırmak için parçacık boyutuna göre hassas bir ayırma gerçekleştirmektir.

(1) Kırma Teknolojisi

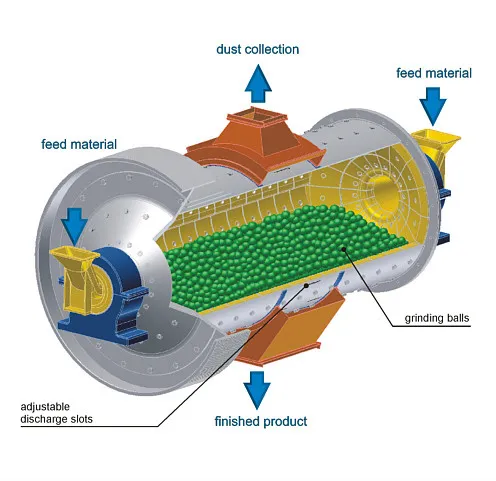

Kuvars kırma işlemi, esas olarak darbe, sıkıştırma ve öğütme gibi mekanik kuvvetlere dayanır. Yaygın olarak kullanılan ekipmanlar arasında çeneli kırıcılar, konik kırıcılar, bilyalı değirmenler, Raymond değirmenleri ve jet değirmenleri bulunur. Kırma işleminde, kuvarsın sertliği (Mohs 7), kırılganlığı ve ayrılma özellikleri dikkate alınmalı, böylece aşırı öğütme işlemi, yabancı maddelerin (örneğin demir, alüminyum) içeri girmesine veya parçacık yüzeylerinin aktive olmasına neden olabilir.

Kaba ve Orta Kırma: Hammadde boyutunu onlarca santimetreden milimetre aralığına düşürmek için genellikle çeneli kırıcılar veya koni kırıcılar kullanılır. Bu aşamada, mekanik aşınmadan kaynaklanan kirlenmeyi azaltmak için kırma oranının (besleme boyutunun ürün boyutuna oranı) 3-8 arasında kontrol edilmesi gerekir.

• İnce Öğütme: Bilyalı değirmenler veya titreşimli değirmenler kullanılarak kuvars parçacıkları mikrometre aralığına (örneğin, D50=10~50 µm) kadar küçültülür. Öğütme ortamının (örneğin, zirkonyum bilyeler, alüminyum bilyeler) seçimi kritik öneme sahiptir; çapraz kontaminasyonu önlemek için sertlikleri kuvarsınkinden daha düşük olmalıdır.

• Ultra İnce Öğütme: Yüksek saflıkta kuvars hammaddeleri için jet değirmenler (örneğin, akışkan yataklı jet değirmenler) veya planet bilyalı değirmenler, mikron altı (D50<1 µm) ultra ince tozlar üretebilir. Jet değirmenler, öğütme için yüksek hızlı parçacık çarpışmalarından yararlanarak demir kontaminasyonunu etkili bir şekilde önler, ancak daha yüksek enerji tüketimine sahiptir.

Tablo: Yaygın Kuvars Kırma Ekipmanlarının Performans Karşılaştırması

| Ekipman Türü | Ürün Parçacık Aralığı (µm) | Kontaminasyon Riski | Enerji Tüketimi | Uygulanabilir Aşama |

| Çeneli Kırıcı | 50~500 | Orta | Düşük | Kaba Kırma |

| Bilyalı Değirmen | 1~100 | Yüksek | Orta | İnce Öğütme |

| Jet Değirmeni | 0.1~10 | Düşük | Yüksek | Ultra İnce Öğütme |

(2) Sınıflandırma Teknolojisi

sınıflandırma Kuvars parçacıklarını boyut, yoğunluk veya şekil temelinde ayırma işlemidir ve yoğun parçacık boyut dağılımına sahip bir ürün elde etmeyi amaçlar. Sınıflandırma ekipmanları, siklon sınıflandırıcılar, hava sınıflandırıcılar, hidrosiklonlar ve titreşimli elekler dahil olmak üzere kuru ve ıslak tiptedir.

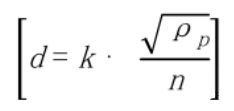

• Kuru Sınıflandırma: Kuru öğütme işlemleri için uygundur jet öğütme, bir hava akımı içindeki santrifüj kuvveti veya atalet farklarını kullanarak parçacıkları ayırır. Örneğin, bir turbo hava sınıflandırıcısı, cihaz ve parçacık yoğunluğuyla ilgili sabitlerin geçerli olduğu rotor hızını (n) ayarlayarak kesme noktasını (d) kontrol edebilir.

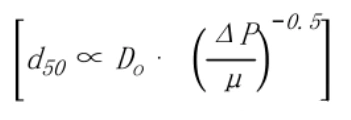

• Islak Sınıflandırma: m.mSu ortamında gerçekleştirilir ve partikülleri tortulaşma veya santrifüj kuvvetiyle ayırır. Hidrosiklonlar, sınıflandırma için bir santrifüj kuvveti alanı kullanır. Kesim boyutu (d50), taşma çapı (D₀) ve besleme basıncı (μ akışkan viskozitesidir) ile ilişkilidir. Islak sınıflandırma daha yüksek verimlilik sunar, ancak daha sonra kurutma gerektirir.

(3) Süreç Optimizasyon Noktaları

Kırma ve sınıflandırma verimliliğini artırmak için aşağıdaki parametre kontrollerine dikkat edilmelidir:

1. Parçacık Boyutu Dağılımı: Öğütme süresi ve sınıflandırıcı tekerlek hızı gibi parametreleri ayarlayarak dar bir dağılım elde edin (örneğin, standart sapma σ <1,5) ve sonraki saflaştırmayı etkileyen aşırı kaba veya ince parçacıklardan kaçının.

2. Kirlilik Kontrolü: Poliüretan veya yüksek saflıkta alümina gibi malzemelerden yapılmış astarlar kullanın ve düzenli olarak metal element içeriğini (örneğin demir, krom) test edin.

3. Enerji Dengesi: Aşırı öğütmeyi azaltmak ve birim ürün başına enerji tüketimini düşürmek için “çok aşamalı kırma + sınıflandırma” gibi kapalı devre prosesleri, örneğin “bilyalı değirmen - hava sınıflandırıcı” kombinasyonunu benimseyin.

Kırma ve sınıflandırma süreçlerinin optimize edilmesiyle, asit yıkama ve flotasyon gibi sonraki saflaştırma adımları için yüksek saflıkta, homojen boyutlu kuvars hammaddeleri sağlanabilir ve bu da nihai ürün kalitesinin sağlanması için temel oluşturur.

3.3 Ham Kuvars İçin Ön Saflaştırma Adımları

Ham kuvars için ön saflaştırma adımları temel olarak kırma, eleme, yıkama ve flotasyondan oluşur. İlk olarak, belirli bir parçacık boyutu gereksinimini karşılamak için büyük kuvars cevheri blokları kırılır. Ardından, eleme ekipmanı farklı boyutlardaki kuvars parçacıklarını ayırır. Ardından, kuvars parçacıklarını yıkamak ve yüzeydeki safsızlıkları gidermek için yıkama maddeleri kullanılır. Son olarak, flotasyon ekipmanı kuvars parçacıklarını safsızlıklardan ayırarak daha yüksek saflıkta bir ham kuvars ürünü elde eder.

Aşağıdaki tablo, ham kuvarsın ön saflaştırma sürecindeki her bir adım için işletme parametrelerini temsil edebilir:

| Adım | Çalışma Parametreleri |

| Ezici | Kırıcı modeli, Kırma oranı, Kırma süresi |

| Tarama | Ekran örgüsü açıklığı, Tarama süresi |

| Ovma | Ovma maddesi türü, Konsantrasyon, Ovma süresi |

| Flotasyon | Flotasyon maddesi türü, Konsantrasyon, Flotasyon süresi |

Ayrıca, ham kuvarsın saflaştırma verimliliğini artırmak için manyetik ayırma ve elektrostatik ayırma gibi yardımcı işlemler kullanılabilir. Bu işlemler, ham kuvarstaki manyetik veya iletken safsızlıkları daha da gidererek ürünün saflığını artırabilir.

Seçme Rehberi Öğütme Değirmenleri

Kuvars tozu üretiminde hedef parçacık boyutuna ulaşmak, üretim kapasitesini en üst düzeye çıkarmak ve maliyet verimliliğini sağlamak için doğru öğütme ekipmanının seçilmesi kritik öneme sahiptir. Farklı öğütme teknolojileri, belirli uygulama gereksinimlerine göre uyarlanmış farklı avantajlar sunar.

Aşağıdaki tabloda kuvars tozunun işlenmesinde kullanılan dört yaygın öğütme sistemi karşılaştırılmakta, bunların temel operasyonel parametreleri ve tipik kullanım durumları vurgulanmaktadır.

| Teçhizat | Fiyat | İncelik | Kapasite | Tipik Uygulamalar |

| Bilyalı Değirmen | Yüksek | Kaba toz (80–2500 mesh) | Yüksek | Cevherler, çimento, kuvars tozu |

| Raymond Değirmeni | Düşük | İnce toz (80–325 mesh) | Normal | Metalik olmayan mineraller |

| Dikey Silindir Değirmeni | Yüksek | İnce toz (20–400 mesh) | Normal | Çimento klinkeri, cüruf, kömür, kuvars |

| Jet Değirmeni | Düşük | Ultra ince toz (325–3250 mesh) | Düşük | Ultra ince kuvars, kimyasallar, pigmentler |

Epik Toz

Ham kuvarstan yüksek saflıkta, hassas bir şekilde sınıflandırılmış toza uzanan yolculuk, uzmanlık ve ileri teknoloji gerektirir. Epic Powder, sektöre özel kuvars öğütme ve sınıflandırma çözümleri sunma konusunda uzmanlaşmıştır. Ekipmanlarımız, maksimum verimlilik, minimum kirlilik ve hassas parçacık boyutu kontrolü için tasarlanmıştır ve kuvars ürünlerinizin gelişmiş uygulamalar için en katı kalite standartlarını karşılamasını sağlar. Kuvars işleme sürecinizi dönüştürmek için Epic Powder ile iş birliği yapın; hassasiyet ve saflığın bir araya geldiği bu platform, olağanüstü sonuçlar sunar. Çözümlerimizin üretim hattınızı nasıl optimize edebileceğini ve nihai ürününüzün değerini nasıl artırabileceğini keşfetmek için bugün bizimle iletişime geçin.

"Okuduğunuz için teşekkürler. Umarım makalem yardımcı olur. Lütfen aşağıya yorum bırakın. Ayrıca EPIC Powder online müşteri temsilcisiyle iletişime geçebilirsiniz. Zelda Daha fazla bilgi için.”

— Gönderiler Jason Wang, Kıdemli Mühendis