Gıda sınıfı kalsiyum karbonat nedir?

Modern gıda endüstrisinde, besin değeri, doku ve stabilite arasında mükemmel bir denge kurmak sürekli bir arayıştır. Bu süreçte perde arkasında çok yönlü bir rol oynayan bileşenlerden biri de gıda sınıfı kalsiyum karbonattır. İnce toz işleme alanında önde gelen bir yenilikçi olan Epic Powder, gelişmiş akışkan yataklı jet değirmen teknolojisini kullanarak birinci sınıf gıda sınıfı kalsiyum karbonat üretmekte ve üreticilerin daha güvenli, daha yüksek kaliteli ürünler yaratmasını sağlamaktadır. Bu kapsamlı kılavuz, bu temel katkı maddesi hakkında bilmeniz gereken her şeyi ele almaktadır.

Gıda sınıfı kalsiyum karbonat (CaCO3), gıda ve besin takviyesi endüstrilerinde yaygın olarak kullanılan yüksek saflıkta bir mineral katkı maddesidir. Sıkı saflık ve kalite standartları nedeniyle doğrudan tüketim ve takviye için onaylanmış güvenli bir kalsiyum kaynağıdır. Bilmeniz gereken iki ana kalsiyum karbonat türü vardır: Öğütülmüş Kalsiyum Karbonat (GCC) ve Çökeltilmiş Kalsiyum Karbonat (PCC).

Öğütülmüş Kalsiyum Karbonat (GCC) Doğal kireç taşı veya mermerin ezilmesiyle üretilir. Doğal olarak oluşan bir parçacık boyutu dağılımına sahiptir, ancak ham madde kaynağına bağlı olarak saflığı değişebilir.

Çökeltilmiş Kalsiyum Karbonat (PCC) Kimyasal bir işlem yoluyla sentetik olarak üretilir ve bu da çok daha ince, homojen boyutlu, daha yüksek saflıkta ve kontrollü kristalliğe sahip parçacıklar elde edilmesini sağlar.

Temel Saflık Özellikleri ve Mevzuat Uyumluluğu

Gıda sınıfı kalsiyum karbonat, aşağıdakiler de dahil olmak üzere katı saflık standartlarını karşılamalıdır:

- Ağır metaller limitleriKurşun, arsenik, cıva ve kadmiyum seviyeleri düşüktür.

- Mikrobiyal güvenlikZararlı bakteri ve patojenlerden arındırılmıştır.

- Kimyasal saflıkGenellikle 97%'nin üzerinde CaCO3 içeriğine sahiptir.

- Düzenleyici onayGıda ve İlaç İdaresi (FDA), Gıda ve İlaç İdaresi (EFSA) ve diğer küresel gıda güvenliği kuruluşlarının standartlarına uygun olup, güvenli tüketimi garanti eder.

Yaygın Hammadde Kaynakları

Gıda sınıfı CaCO3'ün kalitesi büyük ölçüde kaynağına bağlıdır. Yaygın hammaddeler şunlardır:

- Doğal kireç taşı ve mermer – Körfez İşbirliği Konseyi üretiminin birincil kaynakları.

- Yüksek saflıkta kalsit yatakları – Ultra ince, yüksek saflıkta tozlar üretmek için idealdir.

- Sentetik üretim – PCC için, parçacık boyutu ve saflık üzerinde hassas kontrol imkanı sunar.

Özenle seçilmiş ham maddelerin kullanılması, gıda sınıfı standartlarını karşılayan, kirlilik içermeyen bir toz öğütme işlemi elde etmek için çok önemlidir. GCC veya PCC tercih edilsin, amaç tutarlı saflık ve temiz etiketli gıda uygulamalarına uygun güvenli kalsiyum takviyesi sağlamaktır.

Gıda Sınıfı Kalsiyum Karbonatın Uygulamaları

Gıda sınıfı kalsiyum karbonat, gıda ve içecek endüstrisinde, özellikle şu amaçlarla yaygın olarak kullanılmaktadır: kalsiyum takviyesiSüt alternatifleri, meyve suları ve unlu mamuller gibi ürünlerdeki kalsiyum seviyesini artırmak için güvenilir bir kaynaktır ve tadı veya dokuyu değiştirmeden beslenme ihtiyaçlarını karşılamaya yardımcı olur.

Bu mineral, zenginleştirme işlevinin ötesinde, birden fazla rol üstlenir: asitliği yatıştırmak için antasit, kıvamı korumak için stabilizatör, hamurun kabarmasını desteklemek için fırıncılıkta kabartma maddesi ve toz ürünlerin akışkanlığını korumak için topaklanmayı önleyici madde olarak görev yapar. Bu çok yönlü kullanımları onu temel bir katkı maddesi haline getirir.

Takviyelere olan ilginin artmasıyla birlikte, mikronize kalsiyum karbonat, tablet ve toz halindeki ürünlerde biyoyararlanımı artırarak kemik sağlığını ve metabolizmayı destekler. Ayrıca, temiz etiket trendleri doğal ve tanınabilir içerikleri öne çıkarırken, gıda sınıfı kalsiyum karbonat mineral bazlı ve GDO'suz olduğu için tercih edilen bir seçenek haline geliyor.

Çok yönlülüğü ve sağlık yararları, özellikle hem etkinlik hem de tüketici şeffaflığını hedefleyen ürünlerde, küresel çapta talebi artırmaya devam ediyor.

Gıda Endüstrisindeki Başlıca Uygulamalar

Gıda sınıfı kalsiyum karbonatın iki temel işlevi vardır: besin değerini artırmak ve kaliteyi iyileştirmek.

Besin Takviyesi:

Beslenme yetersizliklerini gidermek için çeşitli temel gıdalara eklenen, hayati öneme sahip ve uygun fiyatlı bir kalsiyum takviyesidir.

Örnekler: Bebek maması, süt tozu, soya sütü, süt ürünleri, meyve suları, tahıllar, ekmek ve bisküviler.

Kalite ve İşlevsel İyileştirme:

Fırıncılık ve Unlu Mamuller: pH düzenleyici ve hamur güçlendirici görevi görerek gluten ağının oluşumunu iyileştirir. Bu da daha çiğnenebilir erişte, daha sert ekmek ve daha iyi hacim sağlar. Ayrıca ağartıcı ve kabartma maddesi olarak da işlev görür.

Fırıncılık ve Pastacılık: Dolgu maddesi, stabilizatör ve topaklanmayı önleyici madde görevi görür. Çikolata üretiminde kalıplama özelliklerini ve sertliğini artırır.

İçecekler: Çökelti oluşumunu önlemek ve homojen, çekici bir dokuyu korumak için pH düzenleyici ve stabilizatör olarak kullanılır.

Diğer Kullanım Alanları: Hem kıvam arttırıcı, hem maya için besin kaynağı, hem de ayırıcı madde görevi görerek genel işleme verimliliğini ve raf ömrü istikrarını artırır.

Gıda sınıfı kalsiyum karbonat için neden jet öğütme yöntemi kullanılır?

Jet öğütme, kalsiyum karbonatı ultra ince tozlara öğütmek için parçacıkların hava veya inert gazla yüksek hızlı çarpışmalarını kullanır. Mekanik darbeye dayanan geleneksel bilyalı öğütmenin aksine, jet öğütücüler parçacıkları hızlandırmak için basınçlı hava akımları kullanır; bu da parçacıkların çarpışmasına ve kirlenme riski olmadan parçalanmasına neden olur. Bu işlem, metal aşınmasını önlediği ve temiz etiket ve düzenleyici standartlar için gerekli yüksek saflığı koruduğu için özellikle gıda sınıfı kalsiyum karbonat için uygundur.

Hava sınıflandırma değirmenlerine kıyasla, jet öğütme, kalsiyum takviyesi ve gıdalarda topaklanmayı önleyici maddeler gibi uygulamalar için çok önemli olan daha ince ve daha tutarlı bir parçacık boyutu dağılımı sağlar. Gıda uygulamaları için ideal parçacık boyutları tipik olarak mikron altı ile birkaç mikron arasında değişir ve içeceklerde ve takviyelerde tozun akışkanlığını, beyazlığını ve dağılımını iyileştirir.

Detaylı teknik kurulumlarla ilgilenenler için, gelişmiş seçenekleri keşfetmek faydalı olacaktır. hava jeti frezeleme teknolojisi Bu çalışma, jet öğütme yönteminin gıda sınıfı CaCO3 üretiminde sağladığı hassasiyet ve verimlilik kazanımlarına dair değerli bilgiler sunmaktadır.

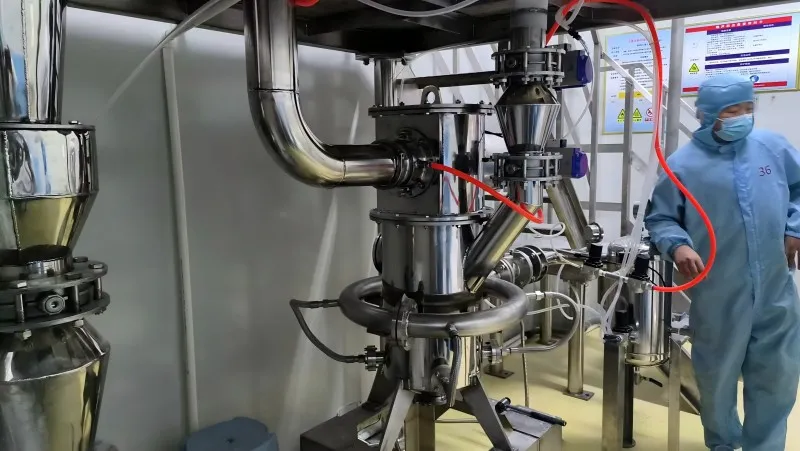

Gıda Sınıfı Kalsiyum Karbonat için Jet Öğütme Prosesi

Gıda sınıfı kalsiyum karbonatın jet değirmeniyle öğütülmesi, genellikle yüksek saflık ve tutarlılık özellikleri nedeniyle özenle seçilmiş ham maddelerle başlar. İşlem, jet değirmenine beslenmeden önce kalsiyum karbonatın kurutulması ve safsızlıkların giderilmesiyle ön temizleme ile başlar.

Jet değirmeninin içinde, yüksek basınçlı hava veya inert gaz, parçacıkları süpersonik hızlarda iterek çarpışmalarına ve ultra ince toza ayrışmalarına neden olur. Hava basıncı, besleme hızı ve sınıflandırıcı hızı gibi temel parametreler, gıda uygulamaları için ideal parçacık boyutu dağılımını (genellikle mikron veya mikron altı aralığında) elde etmek için yakından izlenir ve ayarlanır.

Gıda sınıfı uyumluluğunu sağlamak için, tüm öğütme sistemi paslanmaz çelikten yapılmıştır ve GMP standartlarına göre tasarlanmıştır. İnert gazların (azot gibi) kullanılması, oksidasyonu ve kirlenmeyi önlemeye yardımcı olarak tozun saf ve güvenli kalmasını sağlar. Öğütme işleminden sonra, kalsiyum karbonat toplanır, kalite kontrolünden geçirilir ve bütünlüğünü korumak için hijyenik koşullar altında paketlenir.

Bu temiz ve verimli işlem, besin takviyeleri, gıda takviyeleri ve diğer gıda sınıfı kullanımlar için uygun, kirlenme içermeyen toz öğütme işlemini garanti eder. Hammaddelerden nihai ürünlere kadar olan ayrıntılı süreç için adım adım kılavuza başvurabilirsiniz. Ham maddeden nihai ürüne kadar olan süreç.

Gıda Üretiminde Jet Öğütme Yönteminin Faydaları

Jet öğütme yöntemi, özellikle ultra ince ve saf malzemelere ihtiyaç duyulduğunda, gıda sınıfı kalsiyum karbonat tozlarının üretimi için belirgin avantajlar sunmaktadır.

Başlıca faydaları şunlardır:

| Fayda | Açıklama |

|---|---|

| Üstün saflık | İnert gazların ve paslanmaz çelik parçaların kullanımı, minimum kirlenme riski sağlayarak kalsiyum karbonatın gıda kullanımı için güvenli kalmasını garanti eder. Bu, katı düzenleyici standartları karşılamak için çok önemlidir. |

| Geliştirilmiş beyazlık | Jet öğütme yöntemi, son derece homojen parçacıklar üreterek gıda ürünleri ve takviyelerde arzu edilen parlak beyaz görünümü iyileştirir. |

| Geliştirilmiş akışkanlık | İnce parçacık boyutu, tozun daha iyi akmasını sağlayarak gıda ve içecek formülasyonlarında işleme ve karıştırmayı kolaylaştırır. |

| Daha iyi dağılım | Homojen ultra ince tozlar, sıvılar ve karışımlarda eşit şekilde dağılarak kalsiyum zenginleştirmesini ve dokuyu iyileştirir. |

| Daha yüksek verimlilik | Jet değirmenleri, geleneksel değirmenlere göre daha hızlı bir şekilde ince öğütme sağlayarak işlem süresini ve enerji tüketimini azaltır. |

| Ölçeklenebilirlik | Küçük partilerden büyük ölçekli üretime kadar, jet frezeleme kalite kaybı olmadan kolayca uyum sağlar. |

Bu avantajlar, jet öğütmeyi gıda sınıfı kalsiyum karbonatı ultra ince, tutarlı tozlara öğütmek için en iyi seçenek haline getirerek modern temiz etiketli ve besin takviyesi trendlerini desteklemektedir. Bu işlemin ardındaki teknoloji hakkında daha fazla bilgiyi şu adresten edinebilirsiniz: akışkan yataklı jet değirmeni CaCO3 çözeltileri.

Epic Powder'ın Avantajı: Üstün Kalite için Jet Öğütme

Kaynak malzemeden bağımsız olarak, son öğütme aşaması çok önemlidir. Epic Powder'ın akışkan yataklı jet değirmenleri Gıda sınıfı kalsiyum karbonat üretimi için belirgin avantajlar sunar:

Ultra İnce ve Tutarlı Parçacık Boyutu: Gıda matrislerinde homojen dağılım ve performans için kritik öneme sahip olan, dar bir dağılımla (çoğu zaman mikrometre aralığına kadar) hassas incelik elde eder.

Serin ve Kirlenmeden Arındırılmış Öğütme: Jet öğütme işlemi, minimum ısı üreten basınçlı hava kullanır. Bu, mineralin ısıya duyarlı özelliklerini korur. Ayrıca, sistemin tasarımı aşınmayı ve yıpranmayı en aza indirerek metalik kirlenmeyi önler.

Yüksek Saflık ve Temizlik: Kapalı sistemlerimiz kolay temizlik için tasarlanmıştır ve çapraz bulaşmayı önleyerek nihai tozun en yüksek gıda güvenliği standartlarını karşılamasını sağlar.

Epik Toz

Gıda sınıfı kalsiyum karbonat, sayısız gıda ürününün hem besin değerini hem de fiziksel özelliklerini artıran, vazgeçilmez çok fonksiyonlu bir bileşendir. Güvenli ve etkili kullanımı iki temel üzerine kuruludur: düzenleyici standartlara sıkı bağlılık ve kullanımı yüksek kaliteli, tutarlı şekilde işlenmiş toz.

Güvenilir bir ortak arayan gıda üreticileri için Epic Powder ideal çözümü sunar. jet frezeleme teknolojisi Ürünümüz yalnızca saf ve güvenli olmakla kalmaz, aynı zamanda özel uygulamanızda performans açısından optimize edilmiştir; ister PCC'nin ultra inceliğine, ister GCC'nin maliyet etkinliğine ihtiyacınız olsun.

Epic Powder'ı seçin. Hassas öğütmenin gıda sınıfı mükemmellikle buluştuğu yer.

"Okuduğunuz için teşekkürler. Umarım makalem yardımcı olur. Lütfen aşağıya yorum bırakın. Ayrıca EPIC Powder online müşteri temsilcisiyle iletişime geçebilirsiniz. Zelda Daha fazla bilgi için.”

— Jason Wang, Kıdemli Mühendis