Introduction

Feldspar, as a vital non-metallic mineral resource, occupies an irreplaceable position in fields of ceramics, glass, building materials, and chemical industry, etc. As downstream industries raise increasingly higher requirements for the fineness, purity, and uniformity of feldspar powder, the traditional extensive processing mode can no longer meet the needs of modern production. The feldspar ball mill + classifier production line, with its advantages of stable product quality, high efficiency and low energy consumption, has become the core equipment for feldspar processing.

Qingdao Epic Powder Machinery Co., Ltd., as a professional manufacturer of powder processing equipment, has accumulated more than ten years of production experience and technical expertise in the field of powder equipment. Our company’s ball mill + classifier production line is widely used in the grinding and classification of non-mineral powders. It has high efficiency and low energy consumption, and is well received by customers. Next, combining with our company’s production experience, I will talk about the role of the ball mill + classifier production line in feldspar processing.

Ball mill and classifier production line: equipment coordination and process optimization

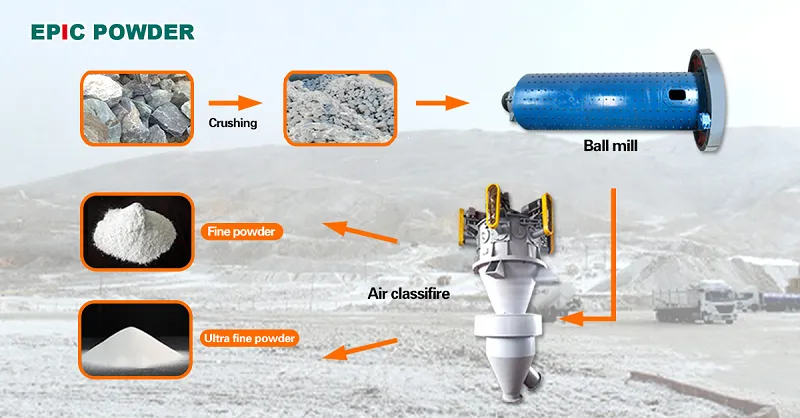

A complete feldspar ball mill and classifier production line consists of a crushing system, a ball milling system, a classification system, and auxiliary systems (such as feeding, conveying, and dust removal). The efficient collaboration of each link is the key to achieving “ideal production”.

1. Ball milling system: the “core engine” of powder refinement

The ball milling system is the “core processing unit” of the feldspar ball milling and classification production line. It undertakes the key task of further refining the crushed feldspar particles to meet industrial requirements. Its performance directly determines the fineness, uniformity and production efficiency of feldspar powder, and serves as the core bridge connecting “crushed raw materials” and “precision classification”.

2. Grading system: the “precise gatekeeper” of product quality

The classifier is a key equipment that determines the fineness of feldspar powder. Its function is to classify the mixed powder after ball milling by particle size, screen out products that meet the requirements (such as -200 mesh, -325 mesh, -1250 mesh, etc.), and return the coarse particles to the ball mill for re-grinding, thus forming a “closed-circuit cycle”.

3. Auxiliary system: “invisible support” for efficient operation of production lines

Although the auxiliary systems do not directly participate in the core processes of feldspar crushing, grinding, or classification, they are like the “blood vessels” and “nerves” of the production line. By connecting various core links, they provide key support for the continuous operation, efficient collaboration, safety, and environmental protection of the entire production line.

Main application of feldspar

Core applications: ceramic and glass industries (accounting for over 95% of global consumption)

Ceramic industry (largest application area, accounting for about 45% of total consumption)

Glass industry (the second largest sector, accounting for about 50% of total consumption)

Application Scenario

Full coverage from laboratory to industrial production

The flexibility of the feldspar ball mill + classifier production line enables it to adapt to production needs of different scales and different fields:

• Small and medium-sized enterprises: A simple production line consisting of a single ball mill + a single classifier can be selected. It requires a small investment, yields quick results, and meets the demand for ordinary feldspar powder in regional markets (e.g., for building materials and low-end ceramics).

• Large enterprises: Configure an intelligent production line with multiple ball mills in parallel and multi-stage classification to achieve large-scale and refined production. It provides high-purity and ultra-fine feldspar powder for industries such as high-end ceramics, electronic glass, and special coatings, with the product added value increased by more than 30%.

Conclusion

In summary, the feldspar ball mill and classification production line, with its refined grinding system, precise screening system, and collaborative support from auxiliary systems, has become a core force in the feldspar processing industry’s transition from extensive to refined, and from traditional to intelligent. Whether it is to meet the basic production needs of small and medium-sized enterprises or to support the high-end and large-scale development of large enterprises, this production line has demonstrated strong adaptability and upgrading potential.

Qingdao Epic Powder Machinery Co., Ltd., with over a decade of expertise, will continue to optimize ball milling and classifying technology, providing customers with more efficient and reliable feldspar processing solutions.

If you are looking to purchase ball mill, classifier, or other powder processing equipment, please contact Epic Powder. Over the years, we have consistently adhered to the principles of high quality, precision machining, and stable production, providing powder processing companies across various industries with reliable equipment and a comprehensive range of services, from pre-sales equipment selection and solution design to after-sales installation, commissioning, and operational guidance, helping powder companies achieve long-term sustainable development in the fierce market competition.